Dasong DS PERIPHERY

Dasong DS TUNGSTEN

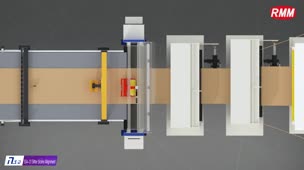

Dasong DS Bridge Web Alignment and Tension Control System

Dasong DS Slitter Scorer Alignment

Dasong BWA-121 Bridge Web Alignment

Dasong DS Liner

Do you know, What’s is the W flute ?

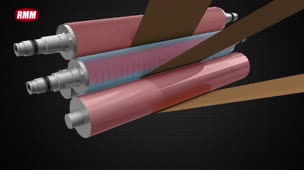

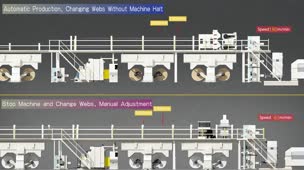

Although there are several flute profiles in the industry that are offered as alternatives to B flute. Dasong(RMM) claims to be the only company that can offer W flute, which has a flute height of 2.2mm. The company says its new flute profile provides better test results by 10 per cent for ECT and 30 per cent for FCT. “We have found that the other common B flute alternatives usually have a flute height of 1.7mm and they are more similar to E flute than B flute,” states llker Arguc, Sales Director, EMEA Region. He continues, “China has in operation every type of corrugator in terms of width, speed, performance and product quality. China is also still using the widest range of corrugated papers of different qualities and gram mages . Manufacturing 3,000 sets of rolls in 2014, Dasong is determined to have a product range covering the requirements of the entire Chinese market.” Mr.Arguc explains, “With the free of charge, tailor-made flute profile design service(TFP), every customer is given the opportunity to evaluate alternative flute profiles by making direct comparison with their current flute profiles . This comparison is made possible thanks to our advanced know-now and our ability to simulate the results of ECT, BCT, FCT and take-up values for tailor-made flute profiles. Customers can make a risk free decision to choose the profiles that best suit their expectations and needs. The main benefits of the TFP service , as confirmed by customers, are that it helps reducing vibration on single facers, especially for lightweight papers. Another benefit is the increase in board strength and control of paper consumption for the targeted board quality.”New W FluteComparison Between W & B FluteUp to 6% TUR Reduction9% Improvement in ECT30% Improvement in FCTLower Logistics Costs Less Vibration “corrugating rolls are among the most risky consumables for corrugators,” comments Peter Ma, Global Sales Director .” Replacing rolls requires an element of time and has high ongoing costs for materials such as bearings and grease . If there are quality issues on the corrugating rolls, it would result in serious product quality issues and an instant increase of waste. Therefore, our Quality Control Department is well organised and inspects every single roll throughly at all stages of the production process. Our inspection results are presented in reports with all the details for the rolls, including reground rolls that might have originated from another manufacturer.”All rolls originally manufactured by Dasong can be reground two times, with guaranteed results. “While some manufacturers have been using softer base materials with 55 HRC hardness to reduce manufacturing costs, Dasong always uses base materials with at least 60-65 HRC hardness before” coating, depending on the brand and type of single facers in order to obtain the best production quality and lifetime,” confirms Mr Ma.” After coating, the hardness of our corrugating rolls reaches 1200HV with tungsten coating and 1000HV with CT coating . There have been many Dasong customers that have reached a lifetime of more than 100 million meters comfortably with tungsten coated rolls .”Another innovative and environmently-friendly decision from Dasong is to replace the traditional chrome coating with a special coating named CT coating , that has been developed and offerred exclusively by Dasong as a lower priced alternative to tungsten coating .” Chrome coating was very popular before the industry had seen the benefits of tungsten coating .” states MrArguc. “With the latest manufacturing technologies , tungsten coating can be precisely applied for all flutes including E and F flutes, but now we can confidently offer CT coating that is proven to have many of the benefits of tungsten coating, including longer lifetime in comparison with the traditional chrome coating. With that said , ninety-per cent of the rolls manufactured by Dasong are still tungsten coated, using the top quality tungsten powders imported both from Europe and the USA.” --If there is any Copyright Dispute, please Contact us to Delete

1946 views0 0

Cheryl Cheng

Regional Sales Manager

Industry experience:5 Year

language:Chinese,English,Vietnamese,Hindu

Responsible area: China,India,Vietnam

Contact