JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

Orite HDF Full servo fixed type

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG VISTEN FLEXO PRINTER

JINCHANG VISTEN FLEXO PRINTER

JINCHANG automatic Flexo Folder Gluer

JINCHANG automatic Flexo Folder Gluer

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG Orite full-servo vacuum suction Flexo Printer Slotter Die cutter

JINCHANG automatic Flexo Folder Gluer

JINCHANG automatic Flexo Folder Gluer

JINCHANG automatic Flexo Folder Gluer

JINCHANG SAIOB Vacuum Flexo Printer Die cutter

JINCHANG SAIOB Vacuum Flexo Printer Die cutter

JINCHANG SAIOB Vacuum Flexo Printer Die cutter

How to avoid printing problems in debugging?

Try This! And Many Common Printing Problems in Debugging Can be Avoided It has skills to debugging printing press, not just by feeling. If you pay attention to the following points, many common carton printing problems can be avoided.1.Make sure adjust the plate pressure to zero : Hanging the plate (preferably full-page), and slowly reduce the gap between the anilox rollers, 90% of the inking area is the zero of plate pressure.Note: The front end of the printing pattern is not neat if the plate pressure is too large. Also, this gap needs to be calibrated monthly.2.Zero adjustment of printing pressure: Take double wall of flute B as an example, slowly reduce the plate gap, ensure 90% of the full-page printing area is inking. At this point, the electronic control value minus the thickness of the cardboard is the zero of the printing pressure. During normal operation, the printing pressure is about 0.2-0.5 mm lower than the cardboard. The back side of the printing surface will be irregular if the pressure too much.Note: This gap needs to be calibrated monthly. 3.The principle of printing feeding roller adjustment ?is the same as printing pressure.4.In principle, the thickness of cardboard should not be reduced by more than 5% during the production, otherwise the carton compression will be seriously affected.5.During the process of production, when the printing press was accelerating, if the cardboard is overall running dislocation, the pressure of the pull rolls should be increased, and the printing pressure should be increased from the back to the front, otherwise the printing blanks will be occurred.6.In the production process, the cardboard without downward warping often appears slotting run-off, the main reason is the transition from the last color of cardboard to slotter entrance is not good, so that the cardboard will hit the lower slotting knife. Problem can be solved by adding transition plate.

1336 views0 0

Printing crushing forms and its effects

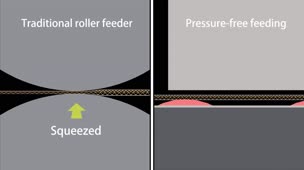

1.Printing crush formsIn the printing production , the cardboard is often crushed, giving rise to the problems such as unprinted patches and printing paste, reduction of the carton pressure resistance, which is a serious problem threatening the production quality. The cardboard crushing is divided into all-crushed, strip crushed and part crushed, we need to make a detailed distinction to the reasons.1).All crushed If the carton is found to be completely crushed, please check whether it is full-page printing on the surface. If not, the crush probably caused by paper feeding roller. If it is full-page printing, first we should release the printing pressure and then feed the paper. If the cardboard is not crushed, it demonstrates that the pressure of printing plate is too much,that’s why to crush the cardboard.2).Strip crushed This is one case of the part crushing, generally the pressure of pull rolls is too large, resulting in cardboard being crushed. At this time the crushed cardboard is in a strip state, and the width is the same with the pull rolls,, this kind is easy to distinguish.3).Part crushed The cardboard crushing area is where the printing pattern is, indicating that the reason for part crushed is the high printing pressure, the crushed size is the same with the printing pattern.Of course, too much die-cutting pressure will also cause cardboard crushed. And the cardboard crushed in terms of the press is probably the too much printing pressure. We should analyze according to actual situation.The impacts of printing crush: 1. When cardboard crushed, it will directly lead to the expansion of printing dot, reducing the printing fineness.2. The crushing will result in the reduction of the carton compression value, generally giving rise to a 10% drop in the carton physical index.3. Printing crush is a production accident, in order to meet customer requirements with demand products, the carton factory will have to rework, which definitely increase the paper costs .

1411 views0 0

Correct operating concepts for printing high quality cartons

In carton enterprises, to make high-quality cartons and achieve good printing effect, both printing captain and operation staffs should establish correct operating concepts and develop standard operation process, and constantly think the improvement of operation according to the problems occurred in the operation process.1.The first operating concept is “gently”The quality of presswork depends on whether the equipment is in good condition, which the key is being “gentle”, including plate pressure, double rollers, scraper pressure, printing pressure, paper pressure, die cutting pressure etc., which are theoretically the lighter the better. First, it is not easy to damage the intensity of cardboard. Second, it’s easy to find problems, for example, when in the printing process, some part of the cardboard can not be printed, in this case, the traditional approach is to continually add pressure, which is the wrong way. The reasons why some part of the cardboard can not be printed are various, such as the plate not in flatness, the mal of the equipment, etc., if blindly adding pressure, cardboard will get crushed.So in the printing process, we should pay attention to the concept of “gently”. If this is not taken seriously, then the service life of the printing press will be short and the quality of the presswork will become worse. The following is a breakdown caused by excessive pressure of the scraper, resulting in an uneven scratch on the presswork.2.The second operating concept is “standardized operations”Usually all the printing parameters should be wrote down, and even some conditions during the operation process should be recorded to form a process standard. For example, plate pressure gap, tranission gap, scraper pressure, printing pressure, paper roller gap, scoring line, ink, PH value, ink viscosity, etc. As process standards, these are the most important factors, we should establish a standard operation, and well record. 3.The third operating concept is “labor division” Printing press is different from production line, which the coordination is achieved by unified command through computer automation, and the entire assembly line. While the printing press is totally another thing. It is usually two or three people to operate a press, especially now the cost of workers, technical staffs is very high, under the condition of technical personnel scarce, some printing press only has two people to operate. In this case, the division of labor is very important, otherwise the efficiency will be affected. The core of printing press operation is the preparation, which takes a long time. In this process, the concept of coordination is the most important part of the printing unit. 1). The coordination of operating process (4-color plate with mold) The traditional printing press is usually operated by three people so as to make high efficiency. First, captain A, he would set the parameters, then take the mold, and install the mold. Second, the deputy B, he would take the plate, put the plate in the press, and get the ink, fill the ink. Third, the deputy C, he would pull the cardboard, and set the stacker behind the printing press at the same time, and then prepare the pallet.After all this steps, the captain begins to adjust the press and the production will be beginning.2).The coordination when operating process is done(4-color plate with mold)When operating is done, they should cooperate with each other. For example, captain A should write reports, clean up defective products and analyze the reasons. Deputy B should remove the mold and printing plate, and deputy C should be responsible for recycling ink. Then make preparation for the next order.

1377 views0 0

Six methods to reduce cartons chromatic difference

1. Stable ink quality Stable ink quality is the key factor to control chromatic difference. Now many customers will compound spot color ink in order to promote the uniqueness of their products and increase security features. Spot color ink ratio must be accurate, so as to ensure a stable ink hue, and the brightness, saturation can meet the requirements.If ink quality changes, it will lead to a large discrepancy. The technical content of ink mixing is relatively high, so the requirements for experience are also very high. If enterprises without owning ink mixing specialist can request ink manufacturers sending technicians to offer door-to-door service. In short, the quality of ink affects the overall effect, it must be carefully selected and used.In the process of using ink, there exists a series of problems including viscosity increase, ink distribution, hue change etc. after volatilizing. These need to be timely adjusted according to specific situation. In the printing operation, front-line staff, especially the captain, will find out many effective methods and all innovations in practice. All proven effective methods should be actively summarized and promoted.2. The inking performance of plate materialThe inking performance of plate material, especially the one wore out after being used for a long time. The progress of plate technology has greatly improved the quality of printing, to a certain extent to reduce the chromatic difference of the presswork, but whether it is rubber plate, resin plate or flexo, long-term wear will greatly reduce its inking performance. Therefore, it will frequently cause problems such as shallow imprinting, unsaturated ink layer. If in this case just add the printing pressure, rather fundamentally solve the problem, it will only lead to plate material further damage and chromatic difference, and carton compression resistance will be greatly reduced.3.Pressure balance, uniform printingThe speed and stability of printing can both lead to color changes. As the printing speed increases, the ink volume increases rapidly, the ink layer thickens and the color increases. On the contrary, when the printing speed decreases, the amount of ink is reduced, the ink layer becomes thinner, the ink is lighter, and the amount of ink is difficult to reach saturation. Therefore, in order to maintain a stable color, it is necessary to maintain a stable printing speed.The same goes for pressure control in printing. Too much pressure, the amount of ink is all, the printing is breezing. Too all pressure on the upper roller, the gap of roller larger, the amount of ink is too much, not only resulting in thick ink layer,hue change, but dot printing will cause paste, and solid field printing will cause creeping.4.Control paper material color, gluing amount, smoothness and other indicators Paper whiteness is included in spectrodensitometer measurement, so measurement and analysis of the chromatic difference among products have to remove the impact of paper color, because the customer will never forgive the chromatic difference caused by the paper factor. Therefore, control paper chromatic difference also become an important job. Especially in the current carton packaging market, the white paper is not used commonly, colored kraft paper, board paper accounted for a larger proportion. Printing on colored paper will produce the effect of “sunglasses”, which should be prevented in the prepress design.Paper smoothness, gluing amount will also cause carton printing chromatic difference. Paper with high oothness will be plane reflection, color will appear bright and light. On the contrary, rough paper will have ink layer diffuse reflection, hue will appear heavy. The gluing amount of the paper will affect ink adhesion, and the thickness of the ink layer directly affects the chromatic difference.5.Strict management system on standard color sample In general, the customer will deliver a standard color sample, if it is a newly developed product, the customer will also confirm a standard color sample before mass printing. Therefore, the customer's color is the standard, color management must be based on the sample color.1).Respect the customer's original standard, do not change without permissionNo matter how many times the plate material is changed, the technical parameters can not be changed, if possible, color density, chromatic difference and other standard items should be recorded into the spectrometer.2). Properly keep to prevent loss, damage or discolorationImproper storage of samples is easy to cause discoloration, once color changed, it will lose the significance of being standard. If used for guiding production, the consequences are unimaginable. Therefore, it is necessary to establish a strict management system to provide a good light-proof and moisture-proof environment.6. Record management Records not only enable product traceability, process records can also enable operations to be traced. According to the requirements of ISO quality management system, there are many kinds of records, which should be done according to document requirements one by one. The projects that really guide production operations and quality control are largely fixed. After each batch of cartons are finished, the ink ratio, viscosity index, printing number, machine speed, operation notes, product inspection and measurement data, even customer comments should be recorded in details. These are truly assets that are conducive to quality improvement and quality improvement.The printing process is variable, and these measures above can not totally ensure there is no chromatic difference. In order to do a good job in color management, and reduce the corrugated box printing chromatic difference, it also requires our crew operators, inspection personnel, management personnel to be careful in observation and adjustment, diligent summary and improvement innovation. In short, color management can achieve the goal of optimizing the carton printing quality.

1567 views0 0

How to Maintain and Use Paper Feeding Roller

At present, most printing presses adopt the leading edge paper feeding. An indispensable part of the leading edge paper feeding is the paper feeding rubber roll. The advantage of paper feeding roller is that it can transfer the paper oothly to the carrying roll, the main of paper feeding roll is to transfer.Friction will be produced in the process of feeding paper, if you do not pay attention to the maintenance during the process, the paper feeding roll will need to be replaced, not only to cause cost waste, but also some other production loss.1.Abrasion is the “biggest killer” of paper feeding rollNow there are more and more manufacturers produce paper feeding roll, the service life of each and every is not the same, feeding roll loss is mainly caused by wear and tear, because paper feeding will produce friction, the circumference of rubber roll after a long time use will be changed, and it needs to be replaced after a certain period of time. 2.Paper feeding roll abrasion will cause mass production wasteLet's do a math: take the configuration of model 1200 as example, if one paper feeding roll is $11, 64 rolls in total for the paper feeding unit, so the total cost is : $11*64pcs = $704, if the maintenance is not well, paper feeding roll will be replaced in half a year, then the spending in one year on the paper feeding roll will be$1,408.But this is not the most important, if the paper feeding roll wear, it will cause slotting shift, color process inaccuracy, printing askew and a series of production losses, not only resulting in production waste, but human cost waste. 3.How to maintain and use the paper feeding roller1) One of the main reasons for paper feeding roll wear is that the paper scraps get stuck between the roll and the supporter, so the position where paper scraps stuck will be immediately worn out when running at high speed. So when foreign matter is found in the front of paper feeding roll, it must be promptly cleaned.2) After a period of time, switch the paper feeding roll, that is to switch the roll at both sides to the middle, be sure to make it on the same level, only in a flat surface, can reduce paper feeding roll wear.3) Paper feeding roll should be regularly cleaned and maintained, alcohol can be used. Do not use toluene for cleaning. After cleaning the paper feeding roll, it can work well, and friction of the paper feeding roll will be increased as well.4) Paper feeding roll rotation with an uneven speed is also a main reason for wear, so we must repair and maintain paper feeding roll when they are rotating slowly.Special reminder: The operator of the printing press should often pay attention to the cleanliness of the paper feeding roll, because the damage of the paper feeding roll directly affects the precision of printing tranission, and sometimes feeding askew may be caused by a damaged paper feeding roll .

1654 views0 0

What should be prepared before carton printing?

1. Check the Process Sheet and Process InstructionAfter having the operation concept, we should check whether the preparation before printing is sufficient. First, to check whether the content of process sheet is complete, such as the notes on process sheet, generally include: printing model, specification, plate number, printing status, numbers etc., Second, to check whether the process instruction is complete. Printing process instruction is a very important process reference for processing before printing. Therefore, we must carefully review before printing.2. Check Sample CartonBecause the colors of carton are various, even the carton, the color can be varied from its nature color to other colors. That’s why even the same color that printed in the different kind of paper would appear differently. In this case, it is vital to check the cartons before printing.3.Check Parameters of EquipmentThe most important thing before printing is to check if the initial parameters of the equipment are correct. The initial parameters refers to whether the gap is reasonable when the equipment is to print the cardboard. We can have a better understanding about whether the gap in the following parts is adjusted properly, including front baffle, side baffle, paper feeding roller, inking roller, printing roller, slotting crush roller, scoring roller, we need to make sure these initial parameters are adjusted to zero before printing. 4 . Check the Ink 1) Hue Check● Use a scraper blade or color wheel to scrape a ribbon on the color paper, then compare with the sample color to determine whether the color is correct. Hue directly affects whether the color of the printed product is correct, which is the first important item of ink quality inspection.● The most objective method is to use the colorimeter. We scan the standard color with the colorimeter , and then scan the color scraped by a scraper, this two colors will form a density difference. But a lot of factories do not have colorimeter, therefore they can only observe with naked eyes, in this way, there is one thing in particular, due to the illuminant difference, inspection result can be greatly different, therefore the illuminance of fluorescent lamp is very important. Make sure to use fluorescent lamps. Some factories use xenon lamps, which will cause problems , especially on night shifts.2) Viscosity CheckIn flexo ink viscosity detection, we usually use Tushi cup and stopwatch, this is the simplest method, its advantages are easy operation and carrying, durable and low price. Of course, there is also a complex method, that is to the use torque viscometer, it is more scientific, being used for experimental calibration, but the actual operation is not very applicable.Requirements of Viscosity Test: a).Before the test, the ink must be mixed evenly;b).Make sure the measuring tool is correct;c). Try not to have foam on the measuring cup;d).Try to control the ink viscosity in 10~30 seconds (No. 4 cup). Generally, the general viscosity is about 24 seconds. 3) PH Value TestPH value is used to test the ink PH, which has a certain impact on the ink viscosity, and ink trapping. Generally, PH value tester is used for detection. PH value detection requirements: the probe should be cleaned, the calibrated button should be pressed before detection, and timely cleaning should be carried out after inspection. This kind of detection is very accurate.Some companies use PH test paper, this method comes with a problem,that is, some color can not be tested, because the PH test paper is detected by discoloration, once other ink sticks on the test paper, it will cause errors.4) Surface Tension TestThe surface tension test is conducted only when there are a lot of hard-to-interpret problems come out. This is not a regular way. Surface tension is measured by a surface tensiometer.5. Check the Plate The printing plate has three layers, the surface is a printing plate, the middle layer is a pad, the back layer is double-sided adhesive tape, the pad and the printing plate will both affect the quality of printing.1) The Hardness of the PlateThe key to check plate is to check the hardness, the surface hardness of 3-7mm resin plate is generally in 30-40 Shore hardness.2) Whether the base of test plate is roughGenerally rough base is caused by the following reasons:underexposure on the back, brush-out pressure and time are not enough, the time of using brush-out potions is too long, exposure is not uniform.Having burrs when the base is rough for printing.3) The surface of the printing plate is crackedThe reason is because the front exposure light distribution is not uniform, curly storage, printing plate is not stored in the dark room, printing plate is oxidized in the air. In the case of plate cracks, cracks will be stained with ink, bring bad effects on the presswork.4) Obvious cracks on the base The main reason is because the exposure time is too long, the base surface hardness is too high, it is easy to crack under a certain tension, so that affects the transfer of ink.5) Check the flatness of the plateBefore make-ready, we should pay great attention on flatness, a lot of people would add more pressure when the printing effect is bad, this is wrong idea. In this condition, we should first check whether the printing plate is flat.6. Check Anilox RollerAnilox roller inspection does not need to carry out very frequently, but must do on regular basis. A high-precision test usually takes two aspects: the amount of ink, and to use a luminous magnifying glass to take a picture.1) Use a professional camera, placed on the anilox roller to film, then it can show the proportion of mesh blocking.2) You can use 60-100 times of luminous magnifying glass, the magnifying glass is placed on the roller, the focal length is adjusted, and the digital camera is placed on the magnifying glass to shoot, it also can obtain the real image of mesh . Once a month or twice a month is acceptable.3) Load the obtained mesh image into the computer, compare the blocking ratio, and judge whether to clean the pattern roller according to the blocking situation.The new images will be shiny, 10% of the mesh blocking will be blurry, 20% will be dark.4) Scraper inking, if 10% blocked, it should be cleaned immediately, glue roller inking, if 20% blocked, it should be cleaned immediately. It is recommended that you do a simple cleaning in every shift, as cleaning becomes more complicated when the blockage reaches 10% or 20%.Simple cleaning is to use a brush and washing powder, if done every day, then the monthly photo can be completely neglected. The quality of presswork will be very good. There is one thing to remind,that is, different roller with different brush. If ceramic roller, steel brush should be used, if steel roller, then we choose a copper brush, otherwise the roller will be damaged.7. Cardboard InspectionHere are six things to watch out in cardboard inspection: flatness, temperature, humidity, paper PH, ink absorption, paper surface tension.

1450 views0 0

In Plum Rain Season,How to Deal with the Blur and Deinking of Carton Printing?

It is inevitable that plum rain season comes every year, while it is the most likely to appear blur and deinking during carton printing in this rainy season. The main reason is that corrugated board affected by high humidity weather, resulting in soft cardboard, so the printer has to increase the pressure.When the ink transfer to the paper, due to the humidity of corrugated board, print blur is more likely to appear due to the enlarged fonts.In addition, high humidity of corrugated board will also lead to deinking on the printing surface . In this way, how to prevent such situation?1 . Adjust Printing Pressure Feeding gap must be well controlled during the rainy days, thickness of the cardboard should be less than 0.4mm.When the air humidity is large, the cardboard itself is softer than that in the dry air. If the feed gap is too tight, the cardboard will be crushed, then the printing pressure must be increased, so it is easy to cause the paste and deinking. If to reduce the feeding pressure, the hardness of the cardboard can be ensured, printing pressure can be decreased, so as to ensure the clarity of printing. 2 . Printing InkHigh ink viscosity is also an important factor resulting in deinking and blur. Therefore, in the rainy season, the viscosity of the ink must be reduced, while the concentration of ink color should be increased, so the drying speed will be accelerated, avoiding the blur and deinking due to the ink itself.--If there is Copyright Dispute, Please Contact us to Delete.

1619 views0 0

What’s the different between Flexography, lithography and digital printing ?

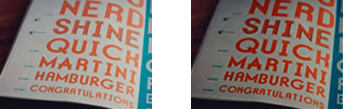

Flexography, lithography and digital are the three basic printing technologies used to applygraphics to corrugated boxes. The purpose of this research is to identify the primary cost driversof selection of a particular process to print corrugated boxes. Flexo post-sheet, flexo pre-print, litho-lamination, and litho-labeling are the four processes traditionally used to print corrugatedboxes. Digital printing processes have been recently introduced to the industry.This research explores the estimated cost of producing a printed corrugated box using thetraditional processes with special emphasis on the relative cost of low volume printing. Itcompares the direct and indirect cost in a cost structure, process drivers in adoption of a printingprocess and the closest compe to digital printing. Cost estimation results reveal that volumeis one of the primary drivers in the selection of a printing process, if the primary criterion forselection is the unit cost of production. ?Quality and speed are the other process drivers. For allthe traditional processes, fixed direct cost is a big part of total cost as opposed to variable directcost for short volume of up to 1500 units. Due to this reason digital printing is very cost effectivein low volume up to 500 units. When cost, quality, and speed are taken into consideration, theprocess that is most similar to digital printing is litho-labeling. Additionally, digital printingoffers other benefits such as customized printing or variable data printing. Flexography (Flexo) Flexo printing is like a “very sophisticated rubber stamp.”This type of printing process prints easily on rough materials like corrugated and ooth materials like coated liners. Good printing speeds and fairly quick set-up time make this a popular and dominate choice for printing on corrugated. Flexo is great for printing on shipper boxes and primary retail packaging. it is often best used to print non-photo quality images using PMS colors instead of 4 color process,as the PMS colors tend to be deeper and more vibrant. The following box uses flexo direct printing onto coated corrugated board.Notice there are non photo quality images in the artwork. Flexo does great with these types of graphics. Not only does this corrugated packaging offer better strength than a standard folding carton box, but the wholesome rustic look suits this product well.When using corrugated for primary retails packaging, it is often desirable to use litho label for eye-catching colors and amazing graphics quality. However this doesn’t always have to be the case as flexo can print photo quality images and do a pretty good job at it . The next image below shows excellent flexographic print directly onto coated(white)corrugated board. The print quality is not nearly as sharp and vibrant as a litho label would have been, but the quality there is still very good for less money than a litho label. Offset lithography (Litho) This print quality is excellent and quite cost effective for high volumes. However ,lithograghic printing predominately used for printing on labels (Called litho labels)which are then glued to the corrugated box, as opposed to any kind of direct litho printing on corrugated boxes. Litho is used if you want stunning photo realistic images as well as foil stamping, embossing, spot gloss or any otherexterior embellishments. Here is an example of a beautiful litho label with a foil stamp on a corrugated retail box.A litho label often times covers the entire box, but is doesn’t nescessarily have to. below is an example of a “spot litho label”. This is where the litho label only covers a portion of the box, while the top of the box, in this case, is direct printedusing flexo. This approach still looks great and can save money.Lithograghy generally come with a higher price tag(unless ordering massive volumes)and tooling, such as printing plates, can be expensive(just like with flexo) which, of course, need to be remade if artwork changes. Digital Printing Digital presses are not unlike digital printers used in homes, And since they use digital files,there is no need for expensive printing plates. There is also virtually no setup required. Digital printing offers higher quality graphics than flexo, and low volumes are ideal, speedy and cost effective. Digital printing is no joke – look at how gorgeous this digitally printed POP display is. This is a direct digital print on E-flute corrugated board. At the moment, digital printing is mostly practical for short runs: test marketing, production shortages, trade show samples etc. But as we all have seen, technology continues to get better and cheaper. It is inevitable that digital printing will one day be the dominate printing method making flexo, litho and all the rest obsolete. Printing speeds will continually increase, quality will became preeminent, and costs will get lower and lower for both high and low volumes.

1817 views0 0

How to calculate the Flexo printing cost accurately?

Flexo printing Cost component contentThis section shows the cost calculation breakdowns for producing different quantities of a 10” x 10” x 10” 200-B RSC corrugated box for a print job using the flexo post-print process. We estimated the total cost of manufacturing in various batch sizes and the computed price for each unit, which includes a profit of 10% (reduced to 6% for bulk orders). The batch sizes are 1, 10,50, 100, 500, 1500, 20,000 and 100,000 print orders. Table 4 shows the results with details about all the direct and indirect costs incurred in the production process.Flexo post-sheet cost estimation for different print quantities.The total cost is calculated as the sum of direct cost and indirect cost. Direct costs include paperboard, ink, printing plates and dies. Paperboard cost includes the cost of corrugation. These costs can be traced to each unit of output. In direct cost, two types of costs are involved, fixed direct cost and variable direct costs and are classified depending upon the print volume. All the paperboard, printing plate, ink and cutting-dies are the fixed direct cost up to a print run of 1500 and they do not change with the print volume up to certain quantity. Whereas, paperboard andink become variable direct cost as they do change with the number of prints unlike printing plateand cutting-dies for a print run of 1500 or more. For example, a run size of 100,000 units will require 5 times as much paper board and ink as a run size of 20,000 units but same printing plate and cutting-dies can be used for both cases. Indirect cost includes all the overhead costs, which cannot be traced to each unit but areallocated using the BHR (budgeted hourly rate) as mentioned earlier in Chapter 3. Productionand labor costs are indirect costs. They are related to operating the machine as well as the laborincurred during the flexo-folder-gluer operation. The rationale of production and labor cost as anindirect cost is that specialized labor is involved in manufacturing and set-up. These workers arenot daily wages or employed on a piece rate system, but are hired on long-term labor contract of 3-5 years on average.We estimated machine running cost, machine set-up cost and labor cost involved in the production and set-up of machine using the Amtech Software. The cost estimates assume that the machine used for production was a Martin Midline flexo-folder-gluer. A BHR for the machine was already loaded in the software, which includes as a BHR library for different machines used in the industry. Indirect cost also includes all other manufacturing overhead such as machine depreciation and machine maintenance, selling overhead such as sales commissions and sales samples, and administrative overhead costs such as human resource, accounting and governance cost.Direct and indirect cost constitutes the total cost. Table 5 and figure 8 show themagnitude of direct cost, indirect cost and total cost per unit for different batch sizes for the flexo post-sheet process, in terms of price per unit. For example, table 5 shows that direct cost for 1 unit is $2,340, so the direct cost per unit forunit quantities is $234. Price/unit cost for direct, indirect and total cost for different print quantities for flexo post-sheet Price/unit cost for direct, indirect and total cost for different print quantities for flexo post-sheet shows that fixed direct cost is a big part of the total cost for quantities up to 1,500. Due to this reason, it is very difficult for flexo post-print process to manufacture and print all prints runs economically. At 1,500 runs or higher, direct fixed cost is distributed over a large quantity and does not affect the price per unit substantially. At higher print volumes, variable direct cost is a big part of the total cost. It shows that substantial magnitudes of total cost are direct cost. This makes the direct cost highly sensitive to total cost. Figure 9 below shows the zoom in view of 500 units or higher.Closer view of the price/unit cost for direct, indirect and total cost for 500 units or higher for flexo post-sheet The price to the customer per box is the sum of direct cost, indirect cost and profit. A standard 10% profit margin is added to the cost up to 1,500 prints and the profit margin is reduced to 6% for bulk orders. Price per unit is calculated by dividing the total “Price to customer’ by the number of units produced. Assumptions about volume discounts were made in the cost estimation to closely nrepresent industry data. These assumptions were based on interviews with industry professionals.Bulk discounts of 10% and 15% are applied to the paperboard cost for quantities of 20,000 and100,000 respectively. A 20% ink discount is applied for quantities of 20,000 and 100,000. A 10% labor discount is applied to quantities of 100,000 quantities and higher. It is clear from the results that as the size of the print order increases, the cost per unit decreases.The reason for the decrease in cost is that as volume increases, several fixed cost and overheads are distributed over a larger number of units, and hence the cost per unit decreases. The result also shows that the flexo-folder-gluer is most cost efficient at 20,000 prints or higher compared to other processes. For example, at 1,500 units, the price per unit is $2.45 which substantially higher than the unit cost of $0.51 for 20,000 units. The overall price is cheaper than litho lamination; however, flexo post-sheet does not provide the quality of lithography.

1617 views0 0