Taiquan TQ-T Automatic Zero Emission Pulping Machine

Taiquan TQ-T Automatic Zero Emission Pulping Machine

Cracking a Sticky Problem: How to Prevent Cracked Scores & Bubbling on Corrugated Board during Litho-Lamination

In the beginning, there were kraft and white boxes with flexographic printing. Then, in the 1980s, the growing influence of big-box retailers forever changed corrugated converting. Instead of hiring sales people, big-box retailers demanded that the corrugated box stand out with a sleek, high-quality graphic that attracted attention and provided sales information to customers. As a result, litho-laminated packaging emerged as a major player in the corrugated industry.For sheet plants, transitioning to litholamination presents opportunities to get into new markets, but it also comes with a few sticky challenges. The process of laminating (gluing) a printed litho-label to double-face corrugated board and then diecutting it can result in cracking on scores during the converting process. And if not applied properly, litholabels can bubble and not lay flat on the board.By taking some relatively easy steps, these problems can be avoided, keeping customers, sales forces and production departments happy; and projects on schedule and most importantly, on budget.There are many potential causes for cracking on scores after a litho-labeled corrugated box is die cut. But one of the primary reasons is also the one most overlooked: glue. A $15,000 litho-label order can be ruined by using $100 of the wrong kind of glue. RESIN AND HYBRID OPTIONSThe most common mistake is using dextrin glue which crystallizes when dried putting additional pressure on the back of the litholabel which leads to score cracking.One solution is to use resin glue. Unlike dextrin, resin glue dries as a pliable film and this reduces the pressure on paper when the score is folded. However, compared to dextrin, resin glue is twice the cost per pound, and it attacks rubber which increases maintenance on laminators.While many sheet plants have already switched from dextrin to resin, there’s a third choice - hybrid glues that have the advantage of both. Like resin, hybrid glue dries as a soft, pliable film; and like dextrin, hybrids are gentle on rubber. There are glue suppliers that have formulated hybrids specifically for litholamination.The cost issue becomes immaterial when you do the math. Do you know how many pounds of glue you use per thousand square feet (MSF)? Chances are you don’t. Few companies weigh the glue tote before and after running a job, and then calculate the MSF through the laminator to determine their usage. In fact, many companies allow laminator operators to use whatever amount of glue they feel is appropriate.Monitoring and controlling the spread rate of glue is vital and should be a part of your production methods. The correct usage of dextrin is a spread rate of 10#/ MSF. For hybrids it can be as low as 6#/MSF. The difference in yields doesn’t completely negate the price difference per pound, but it’s less than $1.50 per MSF, and in most cases, it’s about 50 cents per MSF.A cost increase of $1.50 per MSF for eliminating score cracking is an easy call. One of our sheet plate customers was losing $4,700 in rejected product every time they ran a particular job. After months of trial and error, they consulted with a glue vendor. The cracking on scores disappeared as soon as they switched to the right glue formulated for their Automat?n litho-laminator.While score cracking can be caused by other issues, such as increased recycle content and low-moisture content of the litho-label, glue is the one component that is easy to control both from the type you purchase to the amount you apply.A checklist to prevent score cracking includes:· the right paper· the correct scoring rule· hitting the die board on the correct side· always using matrix *· using low flute profiles· labels with the correct moisture content· storing and using litho-labels in a humidity-controlled environment· resin or hybrid glueBUBBLES, BUMPS AND HUMPSThe problem of bubbling during litholamination tends to occur under areas with heavy ink coverage of dark color (blues and/or black). The cause relates to the affect of liquid on paper fibers. Technically, this is called “hygroexpansivity” - the degree that an increase in moisture content causes fibers to swell, forcing the sheet to expand. After liquid dries, the fiber size decreases, but remains larger than its original size.Think of spilled coffee on paper. After it dries, the paper is rippled due to the fibers’ expansion. If heavy ink areas are surrounded by areas with lighter ink coverage, such as a white border around the edge of the sheet, the fiber growth is manifested by a hump or bubble causing the paper to lift off the surface of the corrugated board after the application of glue.To satisfy customers and achieve what the graphic arts industry calls “rich blacks,” the lithographic printing process usually dictates that dark inks be printed on top of other ink. Similar to flexographic inks, lithographic inks are transparent. In areas with large areas of dark colors the total ink coverage can be 280 percent just shy of three hits. This causes the fiber to grow under these areas. If you examine your laminator while the bubbling is occurring, you’ll notice that initially the litho-label is flat, but over the next few seconds it rises up and forms a bubble. When you cut the area, there’s wet glue under the bubble. The good news is that the solution is inexpensive and simple: a fast-setting glue with a short “open time”-the length of time between the application of glue to the label and when fiber pull-out occurs. If you are using an Automat?n, the open time should be as short as five seconds.

1389 views0 0

Washboarding of Corrugated Cardboard

The success of any packaging is linked closely to its appearance. The global market leads to stronger competition and more similar products to be offered to potential buyers. The appearance of the packaging is the one opportunity to make your product stand out from all the others. Corrugated can deliver a powerful message while offering flexibility in design and concept of the packaging for your products. In addition lamination, printing and labeling can give additional value to your packaging.Washboard effect and fluting defects on packaging is a message about the quality of the product itself.Corrugated offers several unique advantages compared to other materials. Corrugated is high in strength while low in weight. High volumetric efficiency is achieved through high stacking strength and compact, flat size for transportation. It is flexible in box design, low cost even in low volume production and environmentally friendly. Corrugated offers excellent protection for the product whether used as simple shipping container or as a consumer presentation package.You can print on corrugated. But printed corrugated often shows a fluting defect, a consequence of the washboard effect on the liner of the corrugated.The washboard effect, an undulating surface of corrugated card board, is an undesired effect resulting from the corrugated cardboard manufacturing process. The washboard effect can also be seen on corrugated board before printing. Fluting defects are the combination of washboard effects and printing problems including gloss variations, dot gain variations, density variations and trapping variations.Relationship between amount of glueand washboard effectCorrugated board is produced by applying glue to the peaks of the flutes and bonding them to the liner. As the glue dries it shrinks, stretching the liner into the valley between two flutes. The more glue applied, the more water has to evaporate, the more the liner will be stretched, the more washboard effect will appear. There exists a linear relationship between the amount of glue and washboard effect.The moisture content of the air, the paper, and the glue influence the quality of the finished product. High atmospheric humidity, high moisture content in the paper fiber, and high moisture content in the glue will swell the cardboard and reduce the amount of glue applied to the construction. There is a linear relationship between water content and washboard effect: the higher the water content, the lower the washboard effect is.Relationship between moistureand washboard effectThere is a limit in applying water to the process, however. The water needs to evaporate during drying, thus slowing down the process and occasionally damaging the cardboard surface. Side effects like Cockling or Honeycomb may appear when the water content is too high. Cockling and Honeycomb effect due to excessive moistureBecause every corrugator differs in size, age, components involved, format, and many other parameters, it is essential to find the optimal settings to control the process and to keep the process constant.Process variations and washboard effect can lead to high costs because of waste, idle machine time, discussions with customers, additional bad quality rebates, and loss of image.A simple number, quantifying the washboard effect in a repeatable, easy to understand manner is needed. As in other applications such as color or density control, this number can be used in contracts. Agreements about the quality can be easily defined.To meet this requirement Beta Industries introduces the BetaCorr – Corrugated Checker. The BetaCorr is a camera based, hand-held tool that measures the surface of corrugated in a noncontact manner. In a few seconds the microscopic undulations of the surface are analyzed over approximately 1.6 inches taking more than 6,000 depth measurements. The resulting washboard effect is summarized in the WBE value and displayed with a resolution of 1μm.For the first time in the world, the BetaCorr enables you to measure your cardboard directly as it comes out of the processing line. There is no need to prepare samples for measurement. Simply place the device onto the surface and start to measure. If the resulting WBE is higher than allowed, corrective actions can be taken immediately.Preliminary testing in real-world applications is showing an excellent correlation with the visual appearance. Depending on the application and the corrugated composition, different target WBE numbers are typically used. An objective measurement tool for washboard effect will allow you to define your quality parameters upfront, as is done for most other production parameters.

1489 views0 0

Comparative Analysis of Preheater Wrap Control System

A corrugator line should be equipped with multiple preheaters, both single cylinder preheater and multiple preheater. Among them:Medium quality control cylinderBefore the paper feeding into the single facer, plus steam spraying equipment;Linerboard preheaterTo adjust the angle-wrap of paper web before the paper enters the single facer;Multiple preheaterTo heat single corrugator and linerboard before the paper web is fed into the double-sided machine;In the production process of three-layer and five-layer corrugated board, if there is a problem of applying glue, the solution is: through the other direction into the preheater for reverse preheating, that is, to heat the other side of the paper and reverse removal of paper moisture.Usually, a three-layer cardboard production line (one set of single facer) should be equipped with two preheater groups, and a five-layer cardboard production line (two sets of single facer) should be equipped with three preheater groups. If a single facer needs to run a large amount of heavy kraft paper at high speed (more than 350 grams/square meters), equipped with three preheater groups will also play a good role. Seven-layer board production line, heavy duty corrugated board production line can have up to five preheater groups, so that the angle-wrap is more diversified.▲Seven-layer board production line, heavy duty corrugated board production line can have up to five preheater groups, so that the angle-wrap is more diversified.On the preheater, the smaller the angle between the angle-wrap adjusting roll and the paper guide roll, the smaller the contact area between the paper width and the drum dryer; The larger the angle between the angle-wrap regulating roll and the paper guide roll, the larger the contact area between the paper width and the drum dryer. Because the preheater to balance the humidity and moisture content of the base paper, to ensure the smooth production of cardboard, so the preheater has to maximize the angle-wrap adjustment, in order to timely change the heating area of paper web on the drum dryer.▲Comparison diagram of wrap control systemIf the preheater has an encoder interface connected to the production pipe, it can automatically control the angle-wrap——the angle-wrap can be automatically adjusted according to the speed and paper quality, and the length of angle wrap can be calculated automatically. If the preheater does not have an encoder interface to the pipe, the operator manually adjust the angle-wrap. Depending on the operator's personal experience to adjust the size of the angle-wrap is very easy to cause the paper web too wet or too dry, resulting in the production quality of the subsequent process.Comparative analysis of advantages and disadvantages of angle-wrap control system(Table 1)Table 1:Comparative analysis of advantages and disadvantages of angle-wrap control systemIn addition, the current drum dryer of preheated in the market is generally fixed. But equipment suppliers have also developed more advanced configurations that allow the durm dryer to rotate. If the preheater drum dryer can rotate, the surface area of the drum dryer in contact with the paper will no longer be fixed, which is conducive to the uniform use of steam in the drum dryer, on the other hand, it can be more energy saving.

1096 views0 0

Cracking a Sticky Problem: How to Prevent Cracked Scores & Bubbling on Corrugated Board during Litho-Lamination

In the beginning, there were kraft and white boxes with flexographic printing. Then, in the 1980s, the growing influence of big-box retailers forever changed corrugated converting. Instead of hiring sales people, big-box retailers demanded that the corrugated box stand out with a sleek, high-quality graphic that attracted attention and provided sales information to customers. As a result, litho-laminated packaging emerged as a major player in the corrugated industry.For sheet plants, transitioning to litholamination presents opportunities to get into new markets, but it also comes with a few sticky challenges. The process of laminating (gluing) a printed litho-label to double-face corrugated board and then diecutting it can result in cracking on scores during the converting process. And if not applied properly, litholabels can bubble and not lay flat on the board.By taking some relatively easy steps, these problems can be avoided, keeping customers, sales forces and production departments happy; and projects on schedule and most importantly, on budget.There are many potential causes for cracking on scores after a litho-labeled corrugated box is die cut. But one of the primary reasons is also the one most overlooked: glue. A $15,000 litho-label order can be ruined by using $100 of the wrong kind of glue. RESIN AND HYBRID OPTIONSThe most common mistake is using dextrin glue which crystallizes when dried putting additional pressure on the back of the litholabel which leads to score cracking.One solution is to use resin glue. Unlike dextrin, resin glue dries as a pliable film and this reduces the pressure on paper when the score is folded. However, compared to dextrin, resin glue is twice the cost per pound, and it attacks rubber which increases maintenance on laminators.While many sheet plants have already switched from dextrin to resin, there’s a third choice - hybrid glues that have the advantage of both. Like resin, hybrid glue dries as a soft, pliable film; and like dextrin, hybrids are gentle on rubber. There are glue suppliers that have formulated hybrids specifically for litholamination.The cost issue becomes immaterial when you do the math. Do you know how many pounds of glue you use per thousand square feet (MSF)? Chances are you don’t. Few companies weigh the glue tote before and after running a job, and then calculate the MSF through the laminator to determine their usage. In fact, many companies allow laminator operators to use whatever amount of glue they feel is appropriate.Monitoring and controlling the spread rate of glue is vital and should be a part of your production methods. The correct usage of dextrin is a spread rate of 10#/ MSF. For hybrids it can be as low as 6#/MSF. The difference in yields doesn’t completely negate the price difference per pound, but it’s less than $1.50 per MSF, and in most cases, it’s about 50 cents per MSF.A cost increase of $1.50 per MSF for eliminating score cracking is an easy call. One of our sheet plate customers was losing $4,700 in rejected product every time they ran a particular job. After months of trial and error, they consulted with a glue vendor. The cracking on scores disappeared as soon as they switched to the right glue formulated for their Automat?n litho-laminator.While score cracking can be caused by other issues, such as increased recycle content and low-moisture content of the litho-label, glue is the one component that is easy to control both from the type you purchase to the amount you apply.A checklist to prevent score cracking includes:· the right paper· the correct scoring rule· hitting the die board on the correct side· always using matrix *· using low flute profiles· labels with the correct moisture content· storing and using litho-labels in a humidity-controlled environment· resin or hybrid glueBUBBLES, BUMPS AND HUMPSThe problem of bubbling during litholamination tends to occur under areas with heavy ink coverage of dark color (blues and/or black). The cause relates to the affect of liquid on paper fibers. Technically, this is called “hygroexpansivity” - the degree that an increase in moisture content causes fibers to swell, forcing the sheet to expand. After liquid dries, the fiber size decreases, but remains larger than its original size.Think of spilled coffee on paper. After it dries, the paper is rippled due to the fibers’ expansion. If heavy ink areas are surrounded by areas with lighter ink coverage, such as a white border around the edge of the sheet, the fiber growth is manifested by a hump or bubble causing the paper to lift off the surface of the corrugated board after the application of glue.To satisfy customers and achieve what the graphic arts industry calls “rich blacks,” the lithographic printing process usually dictates that dark inks be printed on top of other ink. Similar to flexographic inks, lithographic inks are transparent. In areas with large areas of dark colors the total ink coverage can be 280 percent just shy of three hits. This causes the fiber to grow under these areas. If you examine your laminator while the bubbling is occurring, you’ll notice that initially the litho-label is flat, but over the next few seconds it rises up and forms a bubble. When you cut the area, there’s wet glue under the bubble. The good news is that the solution is inexpensive and simple: a fast-setting glue with a short “open time”-the length of time between the application of glue to the label and when fiber pull-out occurs. If you are using an Automat?n, the open time should be as short as five seconds.

1256 views0 0

Process selection of glue making

Glue is called blood of corrugated board line , the quality of glue, the appropriate proportion will have an important impact on the quality of cardboard.This article mainly introduces the parameter configuration of the glue making process, the selection of the glue making method and the control of the glue amount, etc., hoping that everyone has a clearer and more comprehensive understanding of the glue making process.1.Parameter configuration of glue making(1) Solid content solid content = starch/(water + starch) x 100% (2) Gelatinization TemperatureWinter: 56-58 ℃Summer: 60-62 ℃(3) Viscosity Single facer: 20-25 secondsGluer: 25-30 seconds 2. The process of glue making(1) One-step method (no shrinkage) and two-step method (traditional) :the traditional two-step method has simple operation technology and high viscosity of glue;The one-step method has the advantages of low viscosity, easy gluing and low cost.(2) Selection of tapioca and corn starch (4) How to accurately determine the amount of glueA. Moisture content of normal paper and boardThe current moisture content of cardboard and corrugated paper is (8 + 2) %;Corrugated board national standard (14 + 2) %Note: the excess (6 + 2) % is basically from glue - more glue is more water.B. Relation between the amount of glue and cardboard moistureGenerally, the glue is 1:4 (1 part starch,4 parts water), and the analysis of three current domestic starch consumption:* less than 10g/m2, watering 10 * 4=40g/m2;* less than 14g/m2, watering 14 * 4=56g/m2;* under 18g/m2, the water supply is 18 * 4=72g/m2·Starch consumption increased by 4g, cardboard water increased by 16g/m2;·Starch consumption increased 8g, cardboard water increased 32g/m2Based on the paper formula 120g-95g-100g-95g120g, the basic quantity is 610g/m210 g/m2 production board theory of moisture content :(610 x 40 +)/(610 + 10 + 40) = 13.4% < 14% (National Standard)14 g/m2 production board theory of moisture content (610 * 8%+56)/(610+14+56)=15.4%18 g/m2 production board theory of moisture content (610 * 8%+72)/(610+18+72)=17.1%3.On the premise of good adhesion, the less glue is applied , the betterThe damage of large amount of glue:A. The quality of cardboard is decliningB. Cardboard strength is not up to standardC. The board thickness is not up to standardD. The surface quality of the linerboard is not good and flute exposureE. Corrugated edges wrinkledF. cardboard warpingG. The speed decreases and the production capacity decreasesH. Large glue consumption and economic lossIn a single consumption of 12 g/m2 rose to 14 g/m2, the monthly output in 4 million ㎡Starch loss about $37,000 /year* (14-12 g/m2) x 4 million ㎡ * $400 /ton*12months=$37,000/ year --If there is copyright dispute, please contact us to delete.

1557 views0 0

Two-steps Starch Glue Adhesive Performance of Corrugated Board

Two-step starch adhesive has been widely used in corrugated board assembly line. A large number of production practices show that the adaptability of this adhesive to large production line greatly affects the production efficiency, product quality and energy consumption of corrugated board assembly line. Performance of corrugated paper adhesive are mainly included viscosity (liquid), the drying speed, gelatinization temperature, viscosity, film forming performance, etc., at present, these properties are still has certain problem, such as slow drying speed, high gelatinization temperature, poor initial viscosity ect. How to improve the corrugated board production line adhesive has been a vital research subject. The viscosity of adhesive is one of the key indexes to evaluate the adhesive used in corrugated board assembly line. If viscosity is too big, it is easy to get roller gelatinized, failed to coated, and cause waste; If viscosity is too all, the initial viscosity is not good, resulting in collapsed flute, board crack, and board drying speed is slow, so a proper viscosity is the key.In this article, we analyzed the effect under different reagent dosage on the viscosity of two-step starch adhesive through carrier starch oxidation modification .The Experimental Methods1.1 Carrier StarchAfter mix the water (40 + 2) ℃ with corn starch, slowly add about a quarter of the total NaOH (no more than a quarter, with PH value between 11 ~ 12), then adding catalyst FeSO4, after that adding H202 for a few times.Oxidation for 1.5 ~ 2 h, after oxidation, adding the rest NaOH, stirring it while keeping the temperature not to exceed 50 ℃.1.2 Main starchAdding borax solution that dissolved in hot water before into water(40±2)℃, stir evenly, and add corn starch, keep stirring until completely dispersed evenly.1.3 MixtureSlowly add the carrier starch while keep stirring into the main starch, mix it thoroughly for 20-30min, and keep it warm for another 10-30min.The change of powder water ratio in the experiment was controlled by changing the water consumption. The amount of starch in the carrier: the amount of starch used is about 1:3.5.Discussions on Influencing Factors2.1 Influence of Powder Water RatioLow powder water ratio means less water needs to be evaporated in the drying process, in order to achieve a faster drying speed, the water content in the adhesive should be lower, that is to say, in the premise of meeting other performance requirements, low powder water ratio is good.However, too low powder water ratio is not conducive to the fluidity of adhesive, corrugated board production line has a high liquidity requirements on the adhesive, high fluidity can meet the requirements of rapid, uniform and appropriate coating, obviously, large power water ratio is conducive to decrease the adhesive viscosity. Therefore, we need to find a better water powder ratioin actual production, so as to get a proper viscosity.Table 1 is the influence of water-powder ratio on the viscosity under experimental conditions. The viscosity in the table is determined by the coated 4-cup method.As can be seen from the table, the powder water ratio is better between 1:4.4 and 1:4.8.At this point the viscosity of 37 ~ 53S is more suitable for coating. 2.2 Influence of Oxidant (H202)Oxidation modification mainly through oxidation, so that the glycosidic bond of starch glucose is partially broken and degraded, resulting in depolymerization, molecular weightreduced, and water solubility and affinityincreased, thus, adhesive with high solid content and low viscosity can be prepared, which enhanced drying capacity, and enables oxidation converts the hydroxyl group in starch to an aldehyde group, this will increase the the number of carboxyl groupcombined with paper fibre, as a result,the adhesive force of oxidized starch is greatly improved. In addition, the aldehyde group produced after oxidation has anti-corrosive effect, which improves the anti-corrosive ability of the adhesive, and the carboxyl group significantly improved the stability of the adhesive.The oxidants commonly used in starch adhesives are mainly KMn04, NaCLO and H202. Through comparison, this article selects H202, which has strong oxidation capacity, low dosage, non-toxic, tasteless and colorless, and does not bring impurity ions into the reaction during the oxidation process, as the oxidant of starch carrier.Under the action of H202, the hydroxyl group on the starch glucose unit is transformed into aldehyde group, ketone group, and then oxidized into carboxyl group. The glycosidic bond of the molecule breaks, thus hinders the molecular association, reduces the degree of polymerization, macromolecular degradation, and molecular weight of starch reduced, thus endows the glue liquid with certain fluidity.The oxidized starch obtained by proper control of oxidation degree has good water solubility, affinity, penetrability and adhesion.If the amount of H202 is too much, instead of oxidization, starch will be oxidized too much, which will lead to starch excessive degradation, low viscosity of adhesive, even reduce the bearing capacity and adhesion capacity of the main starch.Table 2 shows the relationship between the viscosity of adhesive and the amount of H202 under experimental conditions.As can be seen from table 2, the viscosity of adhesive changes significantly with the amount of H202. At the beginning, the viscosity decreases rapidly. When the amount of H202 changes around 2.0% (accounting for the total amount of starch), the viscosity of adhesive changes slightly. When the content of H202 exceeds 24%, the viscosity decreases with the increase of oxidant. When H202 is used as oxidant, the viscosity is appropriate from 40 to 46S, so the optimal dosage is 1.6% to 2.4%.In general, the change of H202 dosage between 0.8% and 2.8% does not have obvious influence on the viscosity of adhesive, which is mainly related to the all proportion of carrier starch in the total starch. 2.3 Influence of NaOH DosageNa0H, as a gelatinizer, has three main s: one is to adjust PH value and ensure alkaline oxidation conditions; the other is to combine with hydroxyl group in corn starch, destroying part of hydrogen bond, reducing starch intermolecular forces and lowering gelatinization temperature. The third is to change carboxyl group of oxidized starch into sodium salt and increase hydrophilic and solubility.In fact, oxidized starch itself is insoluble in water, and no adhesion, which needs sodium hydroxide to promote gelatinization, sodium hydroxide integrated with starch molecules in the hydroxyl group, preventing the starch between the hydrogen bond from associating, at the same time, starch swelling and gelatinizing, viscosity largen ,adhesion improved, liquidity stabilized , and storage time being long.Table 3 shows the change of adhesive viscosity with the amount of Na0H.As can be seen from the table, the viscosity of glue liquid almost keeps increasing with the increase of Na0H dosage. When the dosage is 55%, the viscosity has reached 53S; when the dosage continues to increase to 12%, the viscosity is 131S.When the amount of Na0H exceeds 12%, the viscosity shows a downward trend. The reason is that when the alkali solution is added to a certain amount, the starch particles are swollen to a certain extent, and then break up, and become thinner after better dissolution with the alkali solution.From the perspective of fluidity, it is appropriate to control the amount of Na0H at 4.4% ~ 5.5% of the total starch. 2.4 Influence of Borax Amount on ViscosityBorax, as a crosslinking agent, can increase the viscosity of glue solution and enhance the initial viscosity, which is because borax can combine with the aldehyde group and carboxyl group of fully expanded oxidized starch as ligands to form polynuclear ligand compounds.Borax dosage is too much, will lead to product with high cohesion , and produce gel;If the dosage is too little, the complexation effect and the initial viscosity cannot be reached.Table 4 shows the increasing relationship between borax content and viscosity under the experimental conditions.As can be seen from the table, with the increase in the amount of borax, the viscosity has been on an upward trend, when the amount of borax is within the range of 0.8% ~ 1.4%, the viscosity between 40 ~ 49S is the usable range. 2.5 Influence of Catalyst Addition on Viscosity2.5.1 Influence of Catalyst Addition Order on ViscosityThe order in which the catalyst and a all amount of Na0H were added to adjust the PH value had different effects on the experimental results.It was found in the experiment that when adding a all amount of Na0H and then FeS04, the color of glue produced was light yellow, and the viscosity was 4~6S higher than that when adding a all amount of Na0H added after the ferrous sulfate, while adding a all amount of FeS04 and then Na0H, the color of glue produced was milky white.The reason may be that when Na0H was added first, most of Na0H was involved in the gelatinization of starch, and a very all amount of OH- and Fe2+ formed Fe(OH)2 precipitation. The extra amount of Fe2+ caused partial ineffective decomposition of H2O2, and the amount of H2O2 involved in oxidation was reduced. The oxidation was not more sufficient than that when FeS04 was added first, resulting in a higher viscosity than that when FeS04 was added first.When FeS04 is added first and then Na0H, Fe2+ and OH- precipitate immediately. PH value decreased as H2O2 added, Fe(0H)2 has a certain degree of solubility, and slowly enters the role of catalyst, so that H2O2 can more fully achieve the purpose of oxidizing starch, thus reducing the viscosity of glue. In addition, H2O2 itself has bleaching effect, so the color of glue solution is good.Therefore, the effect of catalyst FeS04 was better if first added than that being added after Na0H .2.5.2 Influence of Catalyst Dosage on ViscosityTable 5 shows the influence of the amount of catalyst ferrous sulfate on the viscosity. With the increase of the amount of catalyst, the viscosity decreases, but the amount of catalyst increases to a certain extent, and the viscosity of adhesive slowly increases.This indicates that Fe2+ can catalyze the oxidation of H2O2 on starch, leading to degradation of starch molecular chain and decrease of viscosity. However, with the increase of Fe2+ dosage, the viscosity increases to a certain extent, possibly because Fe2+ has a certain complexation effect on starch molecular chain. 2.6 Influence of Oxidation Time on ViscosityTable 6 is the effect of oxidation time on adhesive viscosity.Oxidation time is long, oxidation depth is large, viscosity will also decrease.However, if oxidation time is too long, starch molecular chain is too all and short, liquidity is too large, resulting in insufficient coating, poor initial viscosity ,and the cardboard is easy to debonding, strength is not good as well. If oxidation time is too short, it will make starch molecular chain fracture degree insufficiently , cause big viscosity, and the oxidation modification effect is not good enough. 3 . Conclusion3.1 Water powder ratio has a great influence on viscosity of two-step starch adhesive.Considering the viscosity alone, the suitable powder water ratio is 1:4.4 ~ 1:4.7.3.2 Using H2O2 to oxidize starch carrier to improve the carrying capacity and solid content of the main starch , the viscosity of starch adhesive obtained is in the range of 40-50s with a good fluidity, with the amount of H2O2 is 1.6% ~ 2.4%, the amount of Na0H is 4.4% ~ 5% of the total amount of starch, and the amount of borax is 0.8% ~ 1.4%.3.3 Catalyst FeS04 was added before a all amount of Na0H for PH regulation, would make he oxidation reaction more complete and the appropriate oxidation time was 1.5-2h. --If there is Copyright Dispute about the content, please Contact us to Delete.

1538 views0 0

Starch Viscosity and Quality of Corrugated Board

Abstract: viscosity is one of the important indexes to measure the quality of starch gum, which directly affects the quality of corrugated board. Therefore, in production, relevant personnel should observe different production conditions at any time, adjust the required viscosity in time, and make the production process reach the best state.Viscosity refers to the degree of liquid flow of starch glue and also the expression of initial viscosity of starch glue. The optimal range is 20 ~ 40 s. In this range of viscosity, the degree of glue liquid oxygenation is appropriate, no flow, no wire drawing; The amount of glue is easy to control. Long storage life. Whether single face, glue unit, or corrugated board production line are in good operation.Factors affecting starch viscosity 1. 1 Type and Quality of StarchStarch variety, fineness, protein and fat content can affect the viscosity of starch gum, especially protein. If the content of protein and fat in starch is too high (more than 1.1%) and the fineness is lower than 98 mesh (100 mesh screen filtration), even if the degree of oxidation is very high at the time of making, the viscosity at the time of discharging is only 20 seconds. After five to seven days of storage, starch glue will naturally thicken, lose fluidity, and be like jelly, affecting the bonding quality . As long as the degree of oxidation and gelatinization is appropriate, the viscosity of the prepared starch adhesive will be 40 + or 10 s. The viscosity will not change much during the storage period, only the color will be dark. The commonly used tapioca starch, potato starch than corn starch, wheat starch viscosity is higher. The dosage of starch varies according to the specific requirements of the adhesive object. 1. 2 Dosage of Oxidant and Oxidation Time For certain starch, the product performance is different due to different degree of oxidation. The content of sodium hydroxide, water ratio and borax remains unchanged. Under any oxidation time condition, the viscosity of starch gum decreases with the increase of oxidant dosage. This is because the larger the amount of oxidant, the larger the degree of oxidation of starch, the aller the molecules, and the aller the viscosity. When the amount of oxidant is less than 2%, the viscosity is not only affected by the amount of oxidant, but also affected by the oxidation time. When the amount of oxidant was more than 2.5%, the viscosity was less affected by the amount of oxidant, and the viscosity was very all, which may be because the oxidation of starch tends to be complete. The results showed that when the oxidant dosage was between 1.8% ~ 2.5% (measured by the percentage content of starch quality), the viscosity was not only suitable for the production of corrugated board, but also high bonding strength, and its viscosity was less affected by the oxidation time. The specific dosage of oxidant depends on the type and quality of starch. Sodium hypochlorite (10%) is about 28% of starch, hydrogen peroxide (27.5%) is about 4% of starch, and potassium permanganate is about 2% of starch. If excessive oxidant is added in operation, strong reducing agent (such as sodium sulfite, baking soda, etc.) should be added to reduce excessive oxidant and prevent excessive oxidation. For the self-use of all and medium-sized factories, it can be used to oxidize at night to prolong the oxidation time, reduce the dosage of oxidant, reduce the consumption of raw materials, so as to reduce the cost.1.3 Oxidation Temperature The effects of temperature on oxidation reactions are manifold: On the one hand, it can increase the speed and degree of oxidation reaction. The higher the temperature is, the faster the oxidation reaction will be. Under the same conditions, the lower the viscosity of starch adhesive produced will be. On the other hand, it can make starch gelatinize and increase the evaporation of water, make starch glue thicken and do not go against the diffusion and oxidation of oxidant, thus increase the viscosity of starch gum. Appropriate oxidation temperature of 20 ~ 30 ℃.1. 4 Dosage of the Gelatinizer NaOHKeep the dosage of oxidant, water ratio and borax unchanged. Under different oxidation time conditions, the viscosity increases with the increase of NaOH dosage. This is because starch particles have a strong cohesive force, and the water molecules must be introduced into starch particles with the help of NaOH, so that starch particles can expand, generate viscosity, and reduce the gelatinization temperature. The dosage of NaOH has a great influence on the viscosity of starch gum. Therefore, the dosage and temperature should be strictly controlled. The dosage is too all, the gelatinization is not complete, the viscosity is poor, the glue fluid is turbid, the fluidity is poor, not easy to store, affects the starch glue performance. If the dosage is too large, which exceeds all the required amount in the pasting process, the starch molecules will swell and pasting, which is not conducive to the diffusion of oxidants, thus affecting the degree of oxidation of starch. The dosage of NaOH should be observed in practice, generally about 12% of starch is more appropriate. On the other hand, the concentration of NaOH cannot be too high. High concentration, strong reaction when gelatinization, easy to saccharify, so that the gluing machine to shake the gum, the phenomenon of flower glue on corrugated peaks, resulting in unglued cardboard and difficult to dry.1. 5 Dosage of BoraxBorax, as a cross-linking agent, can thicken and improve viscosity, but the dosage should be strictly controlled, usually 1% ~ 2% of starch content.If exceeded, gel will be produced, resulting in high cohesion, which is characterized by high viscosity, poor viscosity and fluidity, difficulty in gluing and brittle adhesive layer.Less dosage, making starch glue thin which is easy to infiltrate into the paper, resulting in low viscosity, poor adhesion force, that caused deflected flute, collapse and degelatinize. 1.6 Water RatioWith the increase of water ratio, while Keeping the dosage and concentration of oxidant, sodium hydroxide and borax as well as oxidation time unchanged, the viscosity of starch glue decreases rapidly. However, when the water ratio exceeds 6, the viscosity is less affected by the water ratio. This is because the viscosity is already low, which almost close to the viscosity of water. The size of water ratio depends on the type and use of adhesive board, usually should be controlled between 4. 5 and 5. 5.1. 7 Storage Temperature , Time and Storage EnvironmentAs the storage temperature increases, the viscosity decreases rapidly. When the starch glue is stored in an airtight container, its viscosity changes very little with the extension of storage time. When stored in an open container, the viscosity is greatly affected by the storage time [3]. This is because the starch glue in the open container is oxidized by the oxygen in the air, while the moisture keeps evaporating, which makes the starch glue more viscous. 2 . Effect of Starch Viscosity on Board QualityWhen the viscosity is high, the fluidity of starch glue is poor, which not only increases the amount of glue consumption, but also causes the paper where on paper deflector of the single-sided machine to have pasting points and other problems such as discontinuous debonding, starch glue lateral ejection, cardboard warping, washboard, corrugated height reduced, and cardboard compression strength reduction, etc.When the viscosity is low and the speed is slow, the gumming roller is not gluing. It is not only easy to lose the paste, which makes the starch glue permeate into the corrugated medium and cardboard too much, resulting in poor adhesion; but also cause problems like washboard (the lighter the weight of liner, the more serious it is), longitudinal warping, cardboard too moist, loose linerboard , linerboard and corrugated medium separate after initial bonding ,which leads to delamination, cardboard adhesion strength is relatively low, blank edge compression strength and cardboard compressive strength reduced accordingly.Low viscosity of starch glue and fast speed of gluing will cause low viscosity starch glue where in the shape of water on the double-sided machine having insufficient gluing amount, and glue liquid deviating from the corrugated direction will be lateral ejection .If it is serious, it may cause the cardboard warping or high humidity, and the adhesive strength, side pressure strength and the compressive strength of the carton will be correspondingly reduced. And there may be a pull chain adhesive cardboard or linerboard layered. Too high or too low viscosity will lead to the linerboard or inner linerboard debonding; Slitting edge single face corrugated board loose; The shape of single-sided paper starch glue In the longitudinal will appear blank traces which is consistent with the shape of finger, unglued and without of starch glue. Cardboard moisture is too high; single face corrugated board sheet edge loose. 3 . Regulation of starch viscosityThe viscosity of starch should be adjusted according to the performance of the paper, the object used and the speed of the corrugated machine, heating capacity and other factors. Generally, the viscosity of starch glue used in production line is within the range of 50 ~ 90 s, and that used in single machine production is between 20 ~ 50 s. The bonding strength of high strength corrugated paper, single side corrugated board and thinner flute color board is about 30 + or 5The bonding strength of normal corrugated paper is about 40 + / 10 s. If the viscosity is too high, the content of starch in the carrier can be reduced or a vat of starch glue with low viscosity can be prepared. If NaOH is excessive, some viscosity stabilizer can be added to inhibit the increase of starch viscosity. The amount of NaOH should be reduced when making new paste at the same time. When the phenomenon of glue thrown appeared due to high viscosity or glue machine failed to use (normal use of starch glue viscosity is related to the speed of glue machine, when speed is slow, viscosity can be moderately higher, and vice versa. with no glue thrown as the principle), some moderate amount of oxidant can be added so as to oxidizing again. Don't add water to dilute, lest appear degelatinize and glue thrown . If the viscosity is too low (below 20 s), borax solution can be added or a vat of starch glue with higher viscosity can be prepared. Moderate starch paste (starch + water) can be added to starch glue, and then stirring evenly, but not long-term storage. If the amount of NaOH is insufficient, add some volume to avoid the viscosity reduced. Starch glue should be sealed in storage, not exposed to the air, to avoid scaling, thickening or frozen. 4 . ConclusionAdhesion is one of the most critical processes of corrugated paperboard production, which has the greatest impact on the quality of paperboard. The quality of adhesion ultimately depends on the quality of starch glue. The viscosity is an important index of starch glue and the volume of viscosity directly affect adhesion performance of corrugated board. Only with stable viscosity can the adhesion quality of starch glue be guaranteed. --If there is Copyright Dispute about the content, please Contact us to Delete.

2784 views0 0

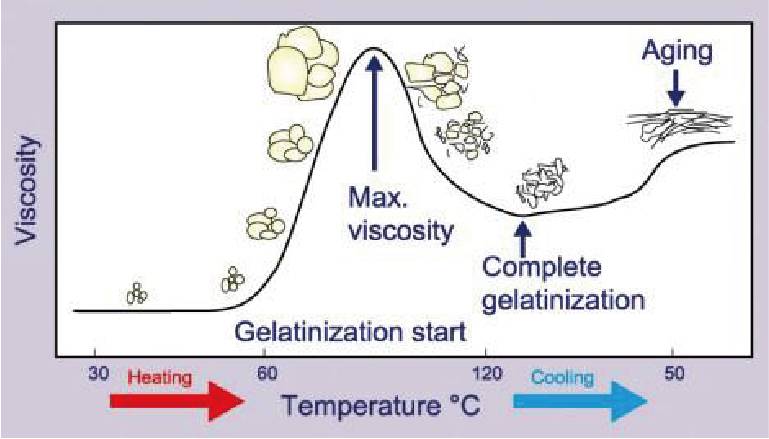

Effect of Starch Gelatinization Temperature on the Quality of Corrugated Board

Gelatinization temperature is one of the important technical indexes of starch glue quality and the standard of gelatinization temperature is 58 + 2 ℃. Generally, the temperature of starch glue in summer is relatively high, paper and mechanical has enough heat to laminating. When gelatinization temperature is high (57-59 ℃), viscosity is relatively stable. The temperature is rather low in winter, so is starch glue. In order to reduce heat that starch glue gelatinization demand, gelatinization temperature should be lowered(55-57℃) to laminating.1. The process of Starch Glue Gelatinization Starch particles were stirred fully under the action of a certain temperature of water, and expanded gradually under the action of the gelatinizer to reach the gelatinization temperature. As the temperature rises, starch particles begin to collapse and gradually disperse into all pieces. When soaked to the inside of linerboard and corrugated medium, they start to bond which require a certain initial viscosity (mainly due to NaOH solution and borax solution). As the temperature rises, the moisture content of starch particles will evaporate, and some of them will be absorbed by linerboard and corrugated medium, so that the initial adhesion will be carried out rapidly. The starch glue will connect inner liner, corrugated medium, flute and linerboard into a whole, so as to achieve the purpose of adhesion. 2. Factors Affecting Gelatinization Temperature of Starch GlueWhen starch glue starts to thicken and the gelatinization temperature is that showing the bonding property due to raw starch gradually gelatinizing among all the starch glue raw materials.There are many factors affecting the gelatinization temperature, mainly in the following aspects.2.1 The Dosage of the Gelatinizer NaOH ① The Effect of the GelatinizerStarch particles itself has a strong cohesive force, water molecules are not easy to infiltrate, so water molecules must be brought into starch particles with the help of gelatinizer, which can weaken the interaction between starch macromolecules and reduce the gelatinization temperature. Secondly, when gelatinizer dissolves in starch solution, it will give out certain heat, making starch particles expand, producing viscosity, and also make starch glue having better fluidity, and not moldy easily.In the carton industry, sodium hydroxide (NaOH) is generally selected as the gelatinizer. The dosage is usually controlled below 1% of the quality of starch glue. It is appropriate to add the oxidized starch solution and stir the starch solution into a translucent paste for 20min.②The Amount of NaOH has a great influence on the Gelatinization Temperature of Starch GlueThe higher the amount of NaOH, the lower the gelatinization temperature with a better infiltration. However, if the weather is too hot, the temperature of starch glue will rise, and the activity of NaOH will increase as well, which will easily cause viscosity rising. Therefore, the amount of NaOH should be slightly adjusted to reach the appropriate gelatinization temperature. Generally, the amount of NaOH should be adjusted with the second amount of NaOH. Large amount of NaOH will cause swelling and gelatinization of starch molecules, resulting in thickening and increase of viscosity (higher than that of 80s). It is not conducive to the diffusion of oxidants, and it is not easy to glue or glue vague.The dosage of NaOH should be reduced according to the situation, and measures should be taken to dilute.If the amount of NaOH is too large, which exceeds all the required amount in the gelatinization process, the glue solution is in high fluidity, which will reduce the viscosity of starch glue and increase the pH value, resulting in yellowing corrugated box and the ink color shifted on the surface of corrugated box. The dosage of NaOH is relatively all., it is white or milky paste 20min after being added, opaque and non-sticky, which under this circumstances is not conducive to the oxidation of starch. The gelatinization is not complete. Glue solution is turbid with a poor fluidity and difficult to storage. If the dosage is too all, characterized by the amount of heat released is less, the gelatinization effect is not sufficient, the viscosity is too low (viscosity is below 20s), and the adhesion force is poor, then the amount of NaOH should be added appropriately according to the situation (the net amount of NaOH used should be clarified). When adding NaOH, fill a certain amount of NaOH with 5-10 times cold water, slowly add it to the container, and continue to stir. In addition, the concentration of NaOH cannot be too high, if so, the gelatinization reaction will be too strong, easy to saccharifying, resulting in glue thrown, and vague glue will be generated on the framed corrugated peak. It will cause debonding and destroy paper fiber and is difficult to dry. when air humidity is large, easy to absorb moisture and yellowing, which generally should be controlled in 10%-13% . The dosage of NaOH should be depended on the actual use, generally about 12% of starch is appropriate.2 . 2 The Type and Quality of Starch Starch is the main adhesive, insoluble in water, expands and gelatinizes with the increase of water temperature. When it acts with NaOH solution, it expands sufficiently and its viscosity increases.The commonly used starch mainly includes corn starch, wheat starch, tapioca starch and potato starch. The variation of gelatinization temperature is due to different producing areas, production climate, brands or quality of starch. The gelatinization temperature of different starch is referred to table 1. Therefore, in practices, combined with the actual situation of each place, choose the lower price starch to produce starch glue. The gelatinization temperature can be adjusted mailnly by changing the amount of sodium hydroxide, and it can be increased by reducing the amount of sodium hydroxide, and vice versa. But remember not to add sodium hydroxide to the prepared starch glue. The gelatinization temperature of starch gum in double corrugated board is lower than that of single ones. This is because the heat transfer of double-sided machine is not as good as single-sided machine, but too low gelatinization temperature often makes the adhesive layer brittle and form surface adhesion. Table 1 Gelatinization Temperature of Different Starch At present, expanding gelatinization is adopted in making various starch gels. The expanded maize starch has loose structure and is spongy and soluble in water. In water, the infiltration, expansion, viscosity, initial viscosity and adhesive strength are enhanced, which makes the expanded corn starch can be directly used as starch adhesive.2.3 TemperatureThe higher the water temperature, the stronger the activity of NaOH, the faster the starch glue viscosity increases, and therefore the lower the gelatinization temperature is. In this case, the amount of secondary NaOH must be reduced to achieve a stable gelatinization temperature, while the lower the water temperature is, the opposite is true.2.4 The Process of Configuration CraftAfter the first addition of NaOH, it should be stirred for 25 + / 5min to have sufficient time to evenly expand and get the correct gelatinization temperature. If the gelatinization temperature is too low, some starch particles will overexpand, while some are not yet expanded, and the viscosity changes greatly, in this case, the amount of NaOH must be reduced. If the gelatinization temperature is too high, the viscosity will be decreased in the text of shear cut during the use, and the amount of NaOH needs to be increased. 3. Effect of Gelatinization Temperature on the Storage Performance of Starch GlueThe biggest defect of starch glue is that it is easy to corrupt and deteriorate, the storage period is short, the service performance is not stable, and the reason why is related to gelatinization temperature. When gelatinization temperature is low, it is easy to cause insufficient gelatinization reaction. The more complete the gelatinization reaction, the longer the storage time of the glue. If starch glue deteriorates during storage from 3 days to 6 months, the reason for the insufficient gelatinization reaction is that ungelatinized starch molecules are more susceptible to bacterial erosion than gelatinized starch molecules.4. Effect of Gelatinization Temperature on the Quality of Corrugated Board When gelatinization temperature is too high, starch glue is not curing, flute tip paste is in white powder, resulting in poor bonding of linerboard, or linerboard loose, linerboard and corrugated medium seperate after preliminary adhesion. When a single-sided machine is running at high speed, continuous unbonded areas, usually spherical swelling, appear in the center of the single-sided web or on a substantial portion of the cross-sectional web, causing the board bubbled.Low gelatinization temperature makes board gelatinized before getting into heating plate , flute tips starch glue blackening and glistening, which cause linerboard in poor laminating. The gelatinization temperature is too high or too low, resulting in poor laminating of inner liner and its sheet edge , flute A and B; as well as in loose slitting edge single face blank linerboard and web edge single face blank. 5 . ConclusionAdhesion is one of the most critical processes in producing corrugated board, which has the greatest impact on the quality of board. The quality of adhesion ultimately depends on the quality of starch glue. Gelatinization temperature is one of the important indexes of starch glue, which directly affects the adhesive performance of corrugated board. Only with stable gelatinization temperature, the bonding quality of corrugated board can be guaranteed. --If there is Copyright Dispute about the content, please Contact us to Delete.

2187 views0 0