NO. 161-3, 20 Lin, Lu Chu Village, Lu Chu Hsiang, Taoyuan Hsien, Taiwan, R.O.C. JIANGSU KUNSHAN JIANGXI YIFENGCHONG QINGDONGGUAN 5 FACTORY ADDRESS

Argentina

Egypt

Ethiopia

Australia

Pakistan

Brazil

Bulgaria

Poland

Germany

Russia

Pilipines

Columbia

Saint Martin

Canada

Cambodia

Zimbabwe

Cayman Island

United States

Bangladesh

Morocco

Mexico

Japan

Switzerland

Serbia

Sudan

Thailand

Turkey

Spain

Singapore

Armenia

Yemen

Iraq

Iran

Israel

India

Indonesia

UK

Jordan

Vietnam

Zambia

Chile

China

HSIEH

Baumer

FUMA

Haili

HSIEH

INDEED

Kadar

RMM

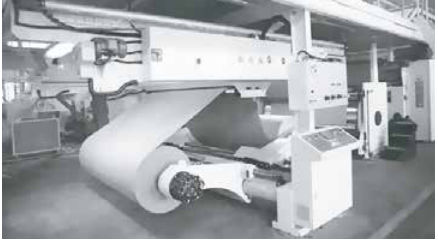

Elements to consider when purchasing double facer

Double facer (hot plate) is the gluing of single face corrugated board and linerboard, heating curing, drying and cold shaping into three wall, five wall or triple wall of corrugated board, and then the corrugated board after the formation of transport to the longitudinal scoring machine and other equipment for cutting and processing cardboard.The double facer is the last part of the wet part of the corrugated line. Its is to complete the final adhesion of the cardboard and the production of flat cardboard. Cardboard out from the double facer whether in the longitudinal or horizontal are stiff and flat, this cardboard is the raw material for the manufacture of cartons. The double facer consists of hot and cold sections.The heating section is composed of several groups of heat oven with ooth surface. Corrugated board is directly attached to it. On the upper plane of corrugated board, there are special canvas belts, pressure rollers or pressure plates with good air permeability, certain tension and gravity, so that corrugated board is heated and dried under certain pressure.Heating section is divided into high temperature zone and low temperature zone, high temperature zone makes the adhesive gelatinization, drying, enhance adhesion.Low temperature area makes corrugated board dry and tend to be stable.The of the cooling section is to dissipate excess heat, evenly distribute water, avoid warping, so that corrugated board into the next process after leveling and shaping.To sum up, the functions of the double facer need to meet the following requirements:1.The paper between the appropriate temperature gelatinization bonding;2.Flute as far as possible to maintain no loss;3. Most economical energy consumption;4. Easy to clean.When paper packaging manufactures purchase double facer, they need to consider the following aspects:1.The choice of pressure plate: pressure plate has three forms: pressure roller, contact pressure plate, air bag pressure plate.2.Heat transfer, mainly consider: (1) steam control system layout;(2) conveyor belt selection.3. Correction mode.4. Install quality and prevent deformation of hot plate.5. Mirror treatment of hot plate when necessary.--If there is copyright dispute, please contact us to delete.

2541 views0 0

How to purchase a satisfactory glue unit?

1. Factors to consider when purchase a glue unitOne of the advantages of the glue unit over the single facer is that there is no need to preheating rollers around the paper during the gluing process.Before the gluing process starts, make sure that the single-sided board should be as ooth as possible when entering the gluing roller clamp.The board can be in contact with the gluing roller through "contact rubber roller" or "contact rod".Contact bars are relatively inexpensive and do not require a lot of effort to maintain, and are perfectly suited to most gluing processes.But if some special cardboard, such as micro corrugated board, then the contact with rubber roller is an advantage, because it is more linear pressure, but also can reduce the flute tip and gluing roller contact arc (compared with the contact bar).The surface of the gluing roller is sandblasted or sculpted, usually with a chrome coating or stainless steel as the raw material. The purpose is still to evenly apply the starch adhesive film to the flute tip.Because the distance to the adhesive is relatively long, so the staying time of starch adhesive on the edge of the flute longer than the single facer on the gluing roller.Some corrugated lines have two sets of starch adhesive circulation system, so on the adhesive machine can choose a higher solid content of adhesive.The speed of the gluing roll of the glue unit is still lower than the paper transfer speed of about 3%, which is conducive to continuous transfer of starch adhesive to the flute point. Wiper roller surface for the flat chromium coating layer or ceramic coating.Starch adhesive tray system is widely used in the glue unit, because of its simple operation, and low temperature environment (relative to the single facer) that means there will be few problems in the tray adhesive gelatinization.Automatic adjustable gluing tray on the glue unit or single facer is equally important, its position should be adjusted to the lower layer of paper edge to 3 mm ~ 4 mm, so as to avoid starch adhesive overflow to the double facer on the hot plate.Without the use of adhesive pallet system, the upper layer will soon harden, and then form a cut edge, the cut edge will damage the subsequent processing of the larger width of the cardboard, if the subsequent processing of the cardboard width is aller will damage the expensive conveyor belt.The lack of this kind of glue tray will make the operation of multiple conveyor belt frequently appear problems. Before the glue unit runs, it is necessary to put an appropriate amount of corn starch adhesive into the upper and lower gluing boxes, and drop the pressure roller. The gap between the pressure roller and the gluing roller should be slightly less than the thickness of the single-sided corrugated board coated, and the size of both ends should be the same.After starting up, adjust the hand wheel to make the gap between the cots and the uniform cots suitable, and observe whether the amount of glue on the cots is appropriate.When single-side corrugated board and surface paper from the multiple preheater transport, with manual guide to the cardboard and linerboard into the preheating roller and cots, and then feeding two layers of single-side corrugated board and one layer of linerboard into the adhesive dryer. Observe whether the pressure roll rotation or collapse, if the pressure roll did not rotate the cardboard but with flute collapse,it is caused by the single facer.If the cardboard with collapsed flute after the glue applying, it is because the gap between the cots and pressure roller is too all, bolt should be pulled up, increase the gap between the pressure roller and the cots.The s of the glue unit shall meet the following requirements:1. Glue the board with the minimum amount of glue;2, Maintain a stable speed while not deguming;3. Maintain the stability of glue quality;4. Easy to clean When purchasing gluing machines, the following six aspects should be considered:1, Gluing quantity adjust type:2. Automatic glue quantity control system;3. Glue temperature control system;4. Glue plate;5. Glue run-out control;6. Slurry board control system. 2.Comparison and analysis of glue roller and press plate The composition structure of the glue unit is mainly composed of upper gluing mechani, lower gluing mechani, linerboard preheating mechanics, operating side protective cabinet, power side protective cabinet, power and tranission system, electronic control system, pneumatic system, etc.glue unit is an essential and important equipment in corrugated board production line. Its is to gluing corrugated paper before it enters double facer forming. The quality of corrugated board products will be directly affected by its performance. Paperboard flatness is not good, paperboard foaming, paperboard fit is not good, bending deformation, paperboard is compressed, paperboard having too much glue, low compressive strength and other problems, are more or less related to the gluing quantity.The traditional way of gluing is accomplished by pressing corrugated paper on the pasting wheel through a pressing wheel. Its disadvantages are as follows: first, it is difficult to adjust the gap between the pasting wheel and the pasting wheel (for example, flute B, the wheel height must be lowered to 2.5 mm to gluing evenly), and it is easy to crush the flute. The crushed corrugated board is easily to gluing too much, that the compressive strength or hardness are both poor, both a waste of glue and pressure of thin cardboard, cardboard is also easy to bend deformation moisture return soft. Second, because of the wear and tear for a long time, the middle part of the glue roll and pressure roll all will be worn down.When processing the board with a wide web, the corrugated cardboard at both ends of the board is easy to be compressed, and the middle position of the gluing is not uniform or even not gluing.The cardboard made in this way is easy to poor gluing, bending deformation is very serious, resulting in a large number of waste. If replace the pressure wheel with the touch-bar, the above cardboard quality problems can be solved.Because the contact bar it is a piece of stainless steel plate and stainless steel spring coated with a special wear-resisting layer and connected together, the spring and wear-resisting pressure plate of the elastic balance of the joint action of corrugated board has always been uniformly pressed on the pasting wheel (regardless of whether the pasting wheel wear), so that the board gluing uniform and not be compressed corrugated.Less gluing and uniform, making flute deformation, such a cardboard compression strength is good, will not bend deformation. There are suppliers with rich experience, can achieve uninterrupted testing torque in order to timely adjust the pressure roller pressure, according to the calculation of torque to control the gap between the applicator roller and gumming roller, applying the glueon the accurate position of flute peak, there will be no collapse of the cardboard phenomenon.Several common load applying glue methods of glue unit, a comparison between advantages and disadvantages (Table 1) Table1:Comparative analysis of three kinds of load gluing methods3 .Automatic glue application control system In the production process of corrugated board, in the premise of ensuring the cardboard adhesion, the less glue the better.If the amount of glue too much, easy to cause cardboard quality decline;Cardboard strength is not up to standard;Cardboard thickness is not up to standard; Linerboard surface quality is not good, flute exposure; edge of cardboard wrinkled;Cardboard warping;Speed down, capacity down;Large glue consumption, economic losses.Traditional mechanical glue control requires manual control of the gap between the scraping wheel and the upper rubber wheel, so as to control the thickness of glue.Generally need operators according to paper and corrugator speed manual adjustment, the disadvantages are frequent and not easy to adjust quickly.The use of automatic glue control system is to achieve in different speed, different paper, tile production system can automatically adjust the amount of glue.The automatic glue control system is helpful to reduce the amount and consumption of glue.Can also reduce scrap cardboard due to human error ;Reduce the original paper waste caused by shortage of glue. Automatic glue control system setting parameters are in PLC, according to the speed and glue formula, according to the set thickness of glue coating automatically adjusted.The disadvantage of automatic glue control system is that although it greatly reduces the workload of manual operation, packaging enterprises should set parameters according to the actual production needs. The central automatic control mode of the glue control system, its PLC can automatically use the paper ,speed in the PCS, automatic calculation of the thickness of the paper, while automatically adjusting the paste cutting clearance, and adjust the riding wheel clearance.Can also use other parameters (such as temperature) of corrugated line , automatically fine-tuning the amount of glue.At present, the technical strength of the equipment suppliers, its corrugated line equipment configuration of the central automatic control mode glue control system, not only can achieve the single facer glue usage control, and each corrugated type is equipped with a set amount of glue curve, and according to the different base paper material with glue offset set .In addition, it can also automatically match the speed of the cots according to the corrugated type, so as to obtain the best gluing effect.The advantages and disadvantages of traditional mechanical glue control system, automatic glue control system and central automatic glue control system are compared as shown in table 2. Table2:The advantages and disadvantages of gluing control system4. Optimization of glue tray Glue application plate of glue unit is generally made of plastic material.The glue tray is provided with a glue liquid inlet at the middle position, a glue liquid groove is provided between the circumference of the glue tray and the glue liquid inlet, and a glue concave is provided at the corresponding glue liquid groove on both sides of the glue tray.The glue tray is also provided with a glue liquid guide outlet, and the glue liquid guide outlet is provided with a glue liquid outlet channel .So, the glue unit not only can smoothly feeding starch, when the plastic plate is dirty or stuck with foreign matters also can facilitate optional to this glue dish undertakes changing, avoid the inconvenience that cleans up.The gluing plate generally has the characteristics of high temperature resistance, low temperature resistance, corrosion resistance, non-adhesion and so on.When the glue unit is configured with gluing plate, the gluing plate,glue tray temperature and the starch run-out should be considered.The glue baffle plate is a wedge shaped baffle inserted between two rollers of the glure and in close contact with the two rollers.When working, the rubber baffle plate keeps the rubber material within the width range of the required roll surface to prevent the accumulation of rubber from running out of the roll surface.If the plastic plate has automatic thermostatic , it can prevent the temperature too low to lead to glue freezing.The reason why the glue is running, one may be the glue viscosity is too big, the other may be the number of anilox roller anilox line is too low.In the actual production process, to control the viscosity of glue, at the same time to use the glue baffle plate, but also pay attention to the configuration of a high number of lines of the anilox roller, the paper on the rubber anilox roller is generally controlled in line 38. Table 3:Several functions of the glue tray --If there is any Copyright Dispute, please Contact us to Delete.

1689 views0 0

Comparative analysis on steam control system

During the operation of the preheater, we should pay attention that whether the condensate water in the steam system is unobstructed. If the condensed water in the drum dryer can not be discharged in time, keeping accumulated will affect the surface temperature of the drum dryer and the preheating effect of the paper.The high temperature condensate produced by the drum dryer of the preheater still has the heat available for use. At present, the method of closed recovery is often used to directly send it back to the boiler for use, which can play the role of energy saving and consumption reduction. ▲Segment Steam System ▲Single-side Steam System ▲Closed Recovery System

1421 views0 0

Comparative analysis on preheater wrap control system

A corrugator line should be equipped with multiple preheaters, both single cylinder preheater and multiple preheater. Among them:Medium quality control cylinder -- Before the paper feeding into the single facer, plus steam spraying equipment;Liner preheater -- To adjust the angle-wrap of paper web before the paper enters the single facer;Multiple preheater -- To heat single corrugator and linerboard before the paper web is fed into the double-sided machine. In the production process of three-layer and five-layer corrugated board, if there is a problem of applying glue, the solution is: through the other direction into the preheater for reverse preheating, that is, to heat the other side of the paper and reverse removal of paper moisture.Usually, a three-layer cardboard production line (one set of single facer) should be equipped with two preheater groups, and a five-layer cardboard production line (two sets of single facer) should be equipped with three preheater groups.If a single facer needs to run a large amount of heavy kraft paper at high speed (more than 350 grams/square meters), equipped with three preheater groups will also play a good role.Seven-layer board production line, heavy duty corrugated board production line can have up to five preheater groups, so that the angle-wrap is more diversified. ▲Seven-layer board production line, heavy duty corrugated board production line can have up to five preheater groups, so that the angle-wrap is more diversified. On the preheater, the aller the angle between the angle-wrap adjusting roll and the paper guide roll, the aller the contact area between the paper width and the drum dryer;The larger the angle between the angle-wrap regulating roll and the paper guide roll, the larger the contact area between the paper width and the drum dryer.Because the preheater to balance the humidity and moisture content of the base paper, to ensure the ooth production of cardboard, so the preheater has to maximize the angle-wrap adjustment, in order to timely change the heating area of paper web on the drum dryer. ▲Comparison diagram of wrap control system If the preheater has an encoder interface connected to the production pipe, it can automatically control the angle-wrap -- the angle-wrap can be automatically adjusted according to the speed and paper quality, and the length of angle wrap can be calculated automatically.If the preheater does not have an encoder interface to the pipe, the operator manually adjust the angle-wrap.Depending on the operator's personal experience to adjust the size of the angle-wrap is very easy to cause the paper web too wet or too dry, resulting in the production quality of the subsequent process. Table 1:Comparative analysis on advantages and disadvantages of angle-wrap control system In addition, the current drum dryer of preheated in the market is generally fixed.But equipment suppliers have also developed more advanced configurations that allow the durm dryer to rotate.If the preheater drum dryer can rotate, the surface area of the drum dryer in contact with the paper will no longer be fixed, which is conducive to the uniform use of steam in the drum dryer, on the other hand, it can be more energy saving. -- If there is any Copyright Dispute, please Contact us to Delete.

1262 views0 0

Technology of paper volume control on bridge stacking

The function of the bridge is mainly to transport the two layers of cardboard produced by the single facer, which will be coated with glue after gradually cooling.Therefore, semi-finished products on the bridge should not be piled up too much, to avoid flute unable to timely heat dissipation by extrusion due to a large number of stacking , resulting in cardboard deformation.In order to avoid this problem, the following measures should be taken in actual production:1. Single facer should keep pace with the speed of double-side locomotive ;2. Add double oblique roll device, so that the two layers of cardboard keep in the middle of the position, affected by bridge suction, quickly aligned on both sides;3. To install ceiling fan or strong exhaust fan in the corresponding place, speeding up corrugated heat dissipation;4. The amount of bridge air suction should be adjusted based on the size of the door, material hard brittle, to avoid breaking or dislocation due to the large or all tension. The speed control of bridge not only avoids the problem of paper tearing, but also affects the accuracy of paper changing in the whole wet part and the automatic compensation of manual paper tearing.The reason is very simple, in the entire corrugated board production line, in addition to the wavy bridge product paper not easy to predict, from the original paper frame to climbing belt, and from the bridge guide to the crosscutting machine distance, is almost constant. It is in fact to calculate the actual amount of stacking paper on bridge, and how to automatically compensate for the amount of bad paper manually torn off on the bridge.At present, there are basically the following calculation methods in the market:Using ink-jet technology, high accuracy: the principle of this way is to install ink-jet machine on corrugated medium, and then in the vicinity of the bridge paper guide induction ink machine, from ink-jet to detection of ink all completed by the computer automatically tracking calculation, so the accuracy can be controlled within 1 meter.Ink-jet device used for measuring the length of stacking paper on bridge of corrugated board production line, including installed on the top of the corrugated tape nozzle body, the nozzle body has the upper end for the ink pipeline to connect the mixing chamber, the lower end of the nozzle body is connected with a liquid cap with an ink hole;There is an empty cavity between the nozzle body and the liquid cap.The lower end of the nozzle body is also provided with a number of crushing holes in the form of through-hole.The mixing cavity and atomizing cavity are connected by a number of crushing holes.Through the ink-jet device,the volume of stacking paper on the bridge can be accurately calculated , so as to effectively reduce the original paper consumption rate.Electric eye detection: the method is to install two reflective infrared detectors on the bridge and calculate the bridge retention by using the relationship between the speed and the speed ratio of the bridge belt.For example, if the distance between two electric eyes is 3 meters, and the speed ratio between the speed of the car and the speed of the bridge belt is assumed to be 6:1, the inferred result is that the distance between the two electric eyes is only 18 meters.This works for users who don't change much with paper;However, for users who use high and low materials with great changes, they may feel confused. Why is it that some materials are accurate in calculation and some errors are as high as 20-30 meters?In fact, the reason is very simple, paper material and thickness are different, so wave size is different in height, so the error value will be high.There are infrared eyes and ink-jet dual identification system, dual control identification rate is high, but also can avoid the lack of ink or water shortage caused by the fault, but the disadvantages of the system installation cost is high, expensive. Comparison of advantages and disadvantages of three common speed control systems on bridge(Table 1)Bridge paper volume appropriate at 70~100m , too much will cause the bending problem of cardboard. We should also notice that the cardboard produced by single facer on the bridge should not be stacked too much, to avoid the double-sided locomotive speed too fast or broken, the machine should always observe the amount of stacking on bridge, keeping the space with the double-sided machine production speed. --If there is any Copyright Dispute, please Contact us to Delete.

1404 views0 0

Analysis on Key points of Bridge Purchase

1.Elements on bridge PurchaseAfter the single-sided board leaves the single facer, it is transported to the overhead bridge via the inclined conveyor belt (the speed is slightly higher than the running speed of the board). The conveyor belt gently clamps the board to avoid the corrugated deformation after the initial bonding.The bridge is composed of paper device, conveyor device, cardboard alignment device, tension adjustment device and walkway on the bridge frame. Single pit board exported from single facer enters the subsequent processing after the paper feeding device, conveying device, aligning board device, tension adjusting device on the bridge conveying frame. The of the bridge is the single-side corrugated board produced by layered wave stacking single facer enables single facer has different speed difference buffer, so that the later stage of the process can not interrupt production. ▲The slanting conveyor belt carries the single-sided cardboard onto the overpass Single-sided board in the longitudinal elastic, and in the transverse is not easy to bend.Single-sided board from the inclined conveyor belt down, need to rhythmically guide down to the horizontal bridge conveyor belt, so that the board can be stacked evenly flat on the horizontal conveyor.The running speed of the horizontal conveyor belt is relatively slow, generally 1/10 ~ 1/7 of the speed of the production line.The of the bridge is to provide buffer stock for the single-sided board, so as to meet the needs of the occasional speed switch between single-sided and double-sided machines.The ideal amount of paper on the bridge should be kept stable and reduced as far as possible, because the atmosphere around the bridge is often warm and wet, if the machine is against the wall, the natural air circulation around the wall will make the machine drive side humidity becomes higher due to less.Just processed cardboard to this moisture absorption capacity, so in that state, the less time the cardboard stay, the more stable the cardboard quality.Most machines have electronic control of the "bridge level control" system, such as paper before the single facer slowed down, the bridge can also quickly adjust the amount of temporary paper.But generally speaking, the bridge can balance the speed of single facer, double facer, so that the bridge product paper keeps in the upper and lower limit.Before the board enters the preheater and gluing machine from the bridge, the board is unfolded and tranitted through the machine to a place several millimeters away from the lower layer of paper.This process requires the use of paper guide, the earliest type of "half-moon" steel guidance paper, but it will damage the edge of the paper, can not achieve the ideal paper guide precision, but also will produce a lot of noise.Most modern machines have one or more soft guide rollers with high surface friction coefficient, which can move on the surface paper and can be replaced at any angle in the desired direction without touching or damaging the edge of the board. ▲A bridge guide pushes the single facer board to the center line or edge One side of the cardboard after the arrangement of another friction surface, that is, through a brake roller, the roller will eventually eliminate the paperboard stacked in the uneven phenomenon and give the paper tension, so that the paperboard then oothly into the preheating machine and gluing machine.If the tension between the single-sided cardboard and the lower layer of paper is very uneven, the cardboard will produce upward warping (often referred to as cardboard "longitudinal warping").Therefore, the brake drum and surface paper brake are effective adjustment equipment, can control the cardboard "longitudinal warping" probaaCorrugated board production line, the s of the bridge to meet the following elements:1. Single-side corrugated paper storage to synchronize gluing machine and single facer.2. Adjust the tension to keep the cardboard flat.3. Adjust the width of single corrugated and surface paper, keep the same width, to reduce trimming and waste.When purchasing bridge, we mainly consider its operation stability, friction coefficient of friction surface, deviation correction ability etc., To sum up, the elements in the procurement of bridge are: 1).The form of bridge deviation correction.2). Tension control form.3).Stacking paper length calculation and control.The following content will make a detailed analysis in the procurement of bridge. 2. Paper guide and tension controlCorrugated board production line tension control and automatic deviation correction has long been an important problem of corrugated board carton enterprises. In the traditional corrugated board production line, the tension and deviation correction of three-layer, five-layer and seven-layer corrugated board is basically completed by vacuum adsorption and electric regulation.Due to the use of mechanical baffle deviation correction, material rupture and paper break occur frequently, resulting in the loss of materials.More importantly, in continuous production, when the size of the base paper changes, the base paper fit dislocation will lead to the double facer on the hot plate has been dry pulp line residue;This will cause the interruption of production, until the operator will clean up the residual paste before continuous production, and ultimately reduce the efficiency of corrugated board production line.The tension of the base paper can be controlled directly or indirectly.Direct control is the actual paper tension value measured by the tension sensor, and then control the speed of bridge drive;Indirect control is to determine the motor speed so as to calculate the tension value of the base paper, and then control the motor speed according to the size of the difference.For the control of the tension of the base paper, the general situation is the combination of indirect control and direct control.Multi-point air bag brake is installed on both sides of the tension system of bridge to make the tension of paper more even and the anti-slip adhesive more durable.Compared with the traditional fan tension system, it is more cost-effective and environmentally friendly.Regarding the deviation correction control and tension control of bridge paper guide, the following two common forms are listed: first, the form of "vacuum suction air + baffle".Old models of equipment are in this form.Its disadvantage is that the suction is relatively all, easy to produce such phenomena as flute exposure;Suction control is not quantified;Manual control baffle reaction is slow, high loss, baffle easy to break the edge of the paper, paper is easy to break.Second, the "brake + servo motor" form.The advantages of this form are: through the servo motor to achieve rapid deviation correction, automatic control can be achieved, and the cardboard alignment is fast;Through brake tension adjustment, digital control can be achieved, while reducing paper break.A comparison of the advantages and disadvantages of the above two forms are as follows: Table1: The advantages and disadvantages of the two tension and deviation correction control systems are compared ▲Through the suction device and baffle to maintain a certain tension and deviation correction ▲Through servo motor and brake for deviation correction and tension control 3. Speed control systemThe of the bridge is mainly to transport the two layers of cardboard produced by the single facer, which will be coated with glue after gradually cooling.Therefore, semi-finished products on the bridge should not be piled up too much, to avoid a large number of piled corrugated by extrusion and unable to timely heat dissipation, resulting in cardboard deformation.In actual production, we should:1). Single facer shall try to keep pace with the speed of double-side locomotive;2). Install double inclined roll device to keep the two layers of cardboard in the center position, and quickly align the two sides under the suction of bridge;3). In the corresponding place to install ceiling fan or strong exhaust fan, speed up corrugated heat dissipation;4). The air intake of the bridge should be adjusted based on the size of the door, the material is hard and brittle , to avoid too much or too little tension caused by breaking or moving. The speed control of bridge not only avoids the problem of paper tearing, but also affects the accuracy of paper changing in the whole wet part and the automatic compensation of manual paper tearing.The reason is very simple, in the entire corrugated board production line, in addition to the wave bridge product paper not easy to predict, from the original paper frame to climbing belt, and from the bridge guide to the crosscutting machine distance, is almost constant.To really calculate, to put it bluntly is how to calculate the actual amount of paper bridge, and how to automatically compensate for the amount of bad paper manually torn off the bridge.At present, there are basically the following calculation methods in the market:Using ink-jet technology, high accuracy: the principle of this way is to install ink-jet machine on the medium, and then in the vicinity of the bridge paper guide induction ink machine, from ink-jet to detection of ink all completed by the computer automatically tracking calculation, so the accuracy can be controlled within 1 meter.Used for corrugated board production line bridge length of paper meter ink-jet device, including installed on the top of the corrugated tape nozzle body, the nozzle body has the upper end for the ink pipeline to connect the mixing chamber, the lower end of the nozzle body is connected with a liquid cap with an ink hole;There is an empty cavity between the nozzle body and the liquid cap.The lower end of the nozzle body is also provided with a number of crushing holes in the form of through-hole.The mixing cavity and atomizing cavity are connected by a number of crushing holes.Through the ink-jet device can be achieved on the corrugated board production line bridge paper volume of accurate calculation, so as to effectively reduce the original paper consumption rate.Electric eye detection: the method is to install two reflective infrared detectors on the bridge and calculate thebridge retention by using the relationship between the speed and the speed ratio of thebridge belt.For example, if the distance between two electric eyes is 3 meters, and the speed ratio between the speed of the car and the speed of thebridge belt is assumed to be 6:1, the inferred result is that the distance between the two electric eyes is only 18 meters.This works for users who don't change much with paper;However, for users who use high and low materials with great changes, they may feel very strange. Why is it that some materials are accurate in calculation and some errors are as high as 20-30 meters?In fact, the reason is very simple, paper material, thickness are different, of course, the bridge shape of the wave is different in size and height, so the error value will be a lot worse.There are infrared eyes and ink-jet dual identification system, dual control identification rate is high, but also can avoid the lack of ink or water shortage caused by the fault, but the disadvantages of the system installation cost is high and expensive.The comparison of advantages and disadvantages of the three common speed control systems on bridge are as follows: Table 2: The advantages and disadvantages of the three speed control systems are comparedBridge paper volume of 70~100m is appropriate, too much will cause the bending problem of cardboard.In the production should also pay attention to the single facer produced cardboard on the bridge should not be too much accumulation, to avoid the double-sided locomotive speed too fast or broken, the machine should always observe the amount of bridge accumulation, with the double facer production speed. --If there is any Copyright Dispute, please Contact us to Delete

1326 views0 0

How to Use Intelligence to Reduce the Loss of Paper Feeding and Paper Splicing?

1. Speed Control of Paper Splicing ProcessPaper speed control refers to the wet end control by monitoring the wet end order paper type length and the length of the base paper running, previously control single facer acceleration, increase the amount of bridge stack paper. When the splicer needs paper splicing, in the state of not reducing the speed of the whole line, reduce the paper splicing speed of the splicer, ensure the success rate of paper splicing, and reduce the loss of paper break. The speed control of paper splicing process can improve the efficiency, ensure the average speed of corrugator production, improve the quality of cardboard, and reduce the labor intensity of workers. Generally corrugated line equipped with production management software (ERP) has a paper connection process speed control .2. Synchronous Speed ControlSynchronous speed control, known as automatic cruise control, is the coordination and automatic matching of the speed of the wet end and the dry end equipment. The wet end control can automatically match the speed of gluing machine and single facer by monitoring the speed of each machine, including the speed of dry part and the amount of paper piled on the bridge, so as to ensure the uniform speed of the whole line. When changing the order speed of dry end, the wet end should be matched with it at the same time, and the amount of paper piled on the bridge should be strictly controlled. Overloading the bridge paper, cardboard is easy to produce warping, crease, affecting the quality of cardboard; Bridge stack paper amount is too all, easy to break the bridge cardboard, resulting in loss. If synchronous speed is well controlled, it can reduce the human error operation, and the labor intensity of workers.Generally corrugated line equipped with production management software (ERP) also has synchronous speed control .3 .Synchronous Order Change ControlSynchronous order replacement control, including bridge stack quantity control and measurement and synchronous paper control. Wet end control through monitoring and calculating the length of wet part replacement order and accurately measuring the amount of paper piled on the bridge, the paper splicing replacement order or synchronous paper splicing replacement order can be carried out to ensure the accuracy of replacement order and reduce the loss of productivity or less production of such orders.Overcapacity and less production are both losses. Less production has to be made up, which will reduce efficiency, increase labor intensity; Overcapacity will affect the consistency of the paper of the next order. So, how to ensure the accuracy of order replacement? As we all know, the distance between the crosscutting machine and the paper splicing points is constant. The only changes are the accuracy of bridge stack paper, the accuracy of different sizes of preheating cylinder envelope angle and the accuracy of paper amount at different positions of the paper free wheel.The Current Measurement Method of Bridge Paper Volume:1) photoelectric measurement, speed and wave size of pitting paper will affect the measurement accuracy, and the error is 2-3m;2) ink-jet or water-jet measurement is more accurate, with an error of about 0.5m; But ink-jet measurement is easy to block the nozzle, but water spray is better. 2 .Increase the encoder of preheating cylinder envelope angle to calculate the paper storage length of different sizes of preheating cylinder envelope angle.3. For the position of the paper splicing free wheel, the length of paper storage at different positions of the paper splicing free wheel can be calculated by adding an encoder. Generally corrugator line equipped with production management software (ERP) also has synchronous speed control , but many factories do not use this , nor the operators like to use. The main reason is that the operation results are not accurate, need to find the reasons from the bridge paper volume, preheating cylinder angle, the position of the free wheel of the paper feeder;Ink-jet measurement is easy to block the nozzle, resulting in damage, so we need to do a good job of cleaning and maintenance.4 .Base Paper Butt Roll Management and ControlThe base paper will more or less form a all butt roll after use. The all roll formed by the base paper after the use is generally placed on the edge of the cardboard line, which is convenient for on-site operators to use. However, the use of all paper rolls will increase the amount of labor of the field operators, resulting in the loss of the use process and the management of the base paper warehouse chaos, increase the frequency of paper in the field, paper management chaos and other phenomena, so as to increase the production cost.In traditional enterprises, butt roll really cannot be managed accurately. After the use of the base paper, the production staff does not know how many meters of the remaining base paper, the planner can not know the number of meters of butt roll, resulting in a large number of butt roll stored in the warehouse.Therefore, most of traditional enterprises are forced to use or carry out paper on site by on-site management. base paper butt roll management, that is, the base paper butt roll weight, length, specifications and other feedback.Intelligent butt roll management can automatically calculate the meters of each roll of paper through the equipment, and real-time monitoring of the number of meters used in the production process and the number of remaining meters.When the base paper is removed from the shelf, the label will be automatically printed. The label will display the remaining length of the base paper, weight, diameter and other data, so that the use of the base paper can be truly controlled.In this way, the list is more convenient, greatly reducing the production of all butt roll; At the same time in the production of orders when the first choice of butt roll, the use of all butt roll is more reasonable, the actual utilization rate of base paper statistics will be more accurate.Therefore, ERP base paper warehouse management can carry out dynamic management of the base paper, save the base paper butt roll weighing and loss in the process, improve the efficiency of the forklift operators, and reduce the cost at the same time. --If there is any Copyright Dispute, please Contact us to Delete

1724 views0 0

How to Reduce Corrugator Line Downtime and Wastage Rate

Abnormal downtime of Corrugated board production line will produce a large number of waste products, reducing production efficiency ,and increasing production costs. Therefore, we should find out the main reasons of corrugated production line down time from five aspects including: operator, machines, materials, regulations, links, and to solve them one by one. As for corrugated production line, in order to reduce production costs, we must ensure a reasonable production schedule, and try to process cartons together with the same quality for different customers. In order to effectively reduce production costs , carton size and other factors should be taken into account to minimize the waste generated by corrugated board production line 1. Scheduling the right production process In order to optimize the cardboard processing area, reduce unnecessary material waste, cardboard areas should be specifically calculated. Same paper quality and width of the base paper should be used when scheduling the production process, and from wide to narrow, so as to reduce the number of paper change, and order change.2. MaintenanceIn order to reduce the downtime rate, it is necessary for us to well maintenance corrugated production line, give full play to the performance of equipment. Improving production efficiency is an effective measure to reduce disguised production costs. Maintenance is carried out by operators and supervised by equipment and management personnel, in particular the bearing lubrication of mechanical equipment, to ensure equipment a good operation. Secondary maintenance should be conducted by equipment maintenance personnel and assisted by operators. We should focus on the leaking and equipment adjustment. Repair means the equipment department develop a detailed overhaul plan and go through it according to the existing problems in the process of use. Among them, daily maintenance is very important, with a low investment cost, but to achieve a good effect. On the one hand, it can extend the service life of equipment, maintaining a normal and ooth operation, on the other hand, reduce the probability of mechanical failure, and the non-inferior products, and meanwhile save manpower and material resources. Besides, we should pay attention on the reasonable inventory of equipment spare parts, which not only reduces the financial pressure, but also ensures a timely maintenance and production of equipment. --If there is any Copyright Dispute, please Contact us to Delete.

1873 views0 0

Creep Characteristics of Multi-layered Corrugated Fibre Board Protective Cushions

Multi-layered corrugated fibreboard, has in recent years been gaining attention as a replacement for polymeric materials for protective packaging for environmental reasons. The properties of pre-compressed multi-layered corrugated fibreboard make it a sustainable replacement for poly-foam and polystyrene. Pre-compressed multilayered fibreboard cushions have most of the structural resistance and damping removed, they behave more like a soft spring. The performance of pre-compressed multi-layered corrugated fibreboard as a protective cushion is influenced by the amount of moisture present. The material stiffness is also dependent on the amount of moisture present. Static compression testing can be carried out to obtain stiffness data by measuring load versus controlled deflection, with stiffness being the load required to deflect a specified distance. The creep properties can be obtained by measuring deflection with a controlled force over a period of time, that is, creep is a measure of deflection per time under a constant force. Chapter 1 Introduction There have been many materials used in the protective packaging area over many decades, such as expanded polystyrene (EPS) and Poly-foams. These materials have been difficult to re-cycle and generally end up in landfill. Paper based materials tend to be more amenable to re-cycling, although more expensive to manufacture. Corrugated fibreboard has been used in the packaging industry for many years mainly as containers and boxes to pack goods for transportation. This material has however can also be used as protective cushions inside containers usually constructed in multiple layers Pre-compressed multi-layered corrugated fibreboard cushions, which is the essence of this study, consists of layers of virgin board glued together then compressed to remove the rigidity and to create a spring like structure. The virgin board usually consists of corrugated fibreboard sheet sandwiched between two plain sheets as shown in Figure 1.1 Figure The flute configuration can be of the following sizes as shown in Table 1-1 with the size shown in yellow being a commonly used size in cushioning. It is felt that the pre-compressed corrugated fibreboard is a good substitute for polymeric materials such as poly-foams and EPS which are commonly used in the packaging industry. As with all cushioning materials it is necessary to determine the cushioning characteristics prior to using as a protective cushion. Within the dynamics and vibrations research group at Victoria University and elsewhere much research has been carried out into the application of virgin and precompressed multi-layered corrugated fibreboard cushions for protective packaging in storage and delivery containers boxes. The main focus has been on the shock attenuation or cushioning characteristics, methods to produce cushion curves using simple compression data and modeling of cushion dynamic behavior and producing records such as impact failure as shown in Figure 1.2.Another dimension to cushion testing is to take into account that when packaged products are in stored in boxes for longer lengths of time, such as in storage, there is a tendency for protective cushions to experience creep or time dependent deformation. The protective cushions lose thickness that leads to a slackening off to the interface between the cushion and the packaged product. This would create direct deterioration of the cushioning effect or loss of support during impact or vibration, and subsequently lead to product damage. One method to overcome this is to allow more cushioning, but to establish how much, requires some knowledge of the creep behaviour. 4 As this product is a paper product there is also the question of humidity affects the creep performance. There has been work produced on the creep behaviour of corrugated fibreboard storage boxes particularly with respect to the effect of humidity. However there seems to be little work on the creep behaviour of corrugated fibreboard protective cushions, especially when the cushions are pre-compressed. There is then a need to study Creep Behaviour of Pre-compressed Corrugated Fibreboard protective cushions. The pre-compression process reveals knowledge of the static compression characteristics of the material which is an adjunct to the creep process. The work for this study is described in the following chapters: The literature review in chapter two talks discusses static compression and creep in corrugated fibreboard and proposes the methodology for this study. Chapter three describes static compression and creep testing procedure. Chapter four provides the analysis of the experimental results and modelling processes. Chapter five contains discussion and main conclusions. Content source: (Study of Creep Characteristics of Multi-layered Corrugated Fibre Board Protective Cushions) Hussein Mahanny Shehab Engineer 2011

1751 views0 0